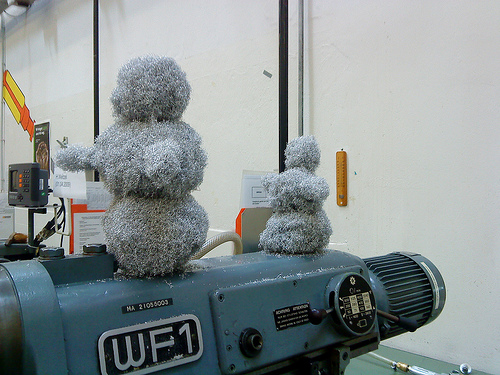

Verify out these aluminium machining china images:

Steven F. Udvar-Hazy Center: Profile view of the SR-71 Blackbird, F-four Corsair, Peashooter, among other folks

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Lockheed SR-71 Blackbird:

No reconnaissance aircraft in history has operated globally in a lot more hostile airspace or with such total impunity than the SR-71, the world’s fastest jet-propelled aircraft. The Blackbird’s performance and operational achievements placed it at the pinnacle of aviation technology developments for the duration of the Cold War.

This Blackbird accrued about 2,800 hours of flight time during 24 years of active service with the U.S. Air Force. On its last flight, March 6, 1990, Lt. Col. Ed Yielding and Lt. Col. Joseph Vida set a speed record by flying from Los Angeles to Washington, D.C., in 1 hour, 4 minutes, and 20 seconds, averaging three,418 kilometers (two,124 miles) per hour. At the flight’s conclusion, they landed at Washington-Dulles International Airport and turned the airplane more than to the Smithsonian.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Corporation

Designer:

Clarence L. "Kelly" Johnson

Date:

1964

Nation of Origin:

United States of America

Dimensions:

General: 18ft 5 15/16in. x 55ft 7in. x 107ft 5in., 169998.5lb. (five.638m x 16.942m x 32.741m, 77110.8kg)

Other: 18ft five 15/16in. x 107ft 5in. x 55ft 7in. (5.638m x 32.741m x 16.942m)

Materials:

Titanium

Physical Description:

Twin-engine, two-seat, supersonic strategic reconnaissance aircraft airframe constructed largley of titanium and its alloys vertical tail fins are constructed of a composite (laminated plastic-sort material) to decrease radar cross-section Pratt and Whitney J58 (JT11D-20B) turbojet engines feature huge inlet shock cones.

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing P-26A Peashooter :

The Boeing P-26A of the mid-to-late 1930s introduced the concept of the high-performance, all-metal monoplane fighter design, which would turn out to be normal in the course of Planet War II. A radical departure from wood-and-fabric biplanes, the Peashooter nonetheless retained an open cockpit, fixed landing gear, and external wing bracing.

Most P-26As stationed overseas had been ultimately sold to the Philippines or assigned to the Panama Canal Division Air Force, a branch of the U.S. Army Air Corps. A number of went to China and one to Spain. This one particular was based at Selfridge Field in Michigan and Fairfield Air Depot in Ohio in between its acceptance by the U.S. Army Air Corps in 1934 and its transfer to the Canal Zone in 1938. It was offered to Guatemala in 1942 and flew in the Guatemalan air force till 1954. Guatemala donated it to the Smithsonian in 1957.

Present of the Guatemalan Air Force, Republic of Guatemala

Manufacturer:

Boeing Aircraft Co.

Date:

1934

Nation of Origin:

United States of America

Dimensions:

Wingspan: 8.five m (27 ft 11 in)

Length:7.three m (23 ft 11 in)

Height:three.1 m (ten ft 2 in)

Weight, empty:996 kg (2,196 lb)

Weight, gross:1,334 kg (two,935 lb)

Best speed:377 km/h (234 mph)

Engine:Pratt & Whitney R-1340-27, 600 hp

Armament:two .30 cal. M2 Browning aircraft machine guns

• • • • •

Quoting Smithsonian National Air and Space Museum | Vought F4U-1D Corsair :

By V-J Day, September 2, 1945, Corsair pilots had amassed an 11:1 kill ratio against enemy aircraft. The aircraft’s distinctive inverted gull-wing design permitted ground clearance for the massive, three-bladed Hamilton Normal Hydromatic propeller, which spanned far more than 4 meters (13 feet). The Pratt and Whitney R-2800 radial engine and Hydromatic propeller was the biggest and a single of the most effective engine-propeller combinations ever flown on a fighter aircraft.

Charles Lindbergh flew bombing missions in a Corsair with Marine Air Group 31 against Japanese strongholds in the Pacific in 1944. This airplane is painted in the colors and markings of the Corsair Sun Setter, a Marine close-support fighter assigned to the USS Essex in July 1944.

Transferred from the United States Navy.

Manufacturer:

Vought Aircraft Company

Date:

1940

Country of Origin:

United States of America

Dimensions:

General: 460 x 1020cm, 4037kg, 1250cm (15ft 1 1/8in. x 33ft five 9/16in., 8900lb., 41ft 1/8in.)

Components:

All metal with fabric-covered wings behind the major spar.

Physical Description:

R-2800 radial air-cooled engine with 1,850 horsepower, turned a 3-blade Hamilton Regular Hydromatic propeller with solid aluminum blades spanning 13 feet 1 inch wing bent gull-shaped on both sides of the fuselage.