Verify out these precision engineering services pictures:

Red Arrows

Image by afaloon

Airbourne is proud to welcome back the RAF Aerobatic Group, the Red Arrows, a single of the world’s premier aerobatic show teams. 2014 marks a unique year for the team who will be celebrating their 50th show season.

With a trademark combination of close formations and precision flying, the Red Arrows have been displaying considering that 1965 and is made up of a team of 120 men and women including pilots, engineers and support employees. They represent the speed, agility and precision of the Royal Air Force and the public face of the service, assist in recruiting to the Armed Forces and act as ambassadors for the United Kingdom promoting the very best of British.

A lot of of the current pilots were first inspired to pursue a career in the military and join the Royal Air Force following watching the Team in the sky as children.

To apply for selection to the Red Arrows, pilots must:

* Have at least 1,500 quick jet flying hours

* Have completed a frontline tour

* Be assessed as above average in their flying role

The Red Arrows are renowned for the visual impact of their red, white and blue smoke trails. Smoke also plays an critical flight security function also allowing the pilots to judge wind speed and direction – enabling them to locate other aircraft when distinct sections of the Team’s formations are several miles apart.

Aircraft Specifications

Dimensions

Height: 4m

Length: 11.85m

Wingspan: 9.39m

Overall performance

Maximum speed: 622mph

Powerplant

Rolls-Royce Turbomeca Adour Mk 861 turbofan

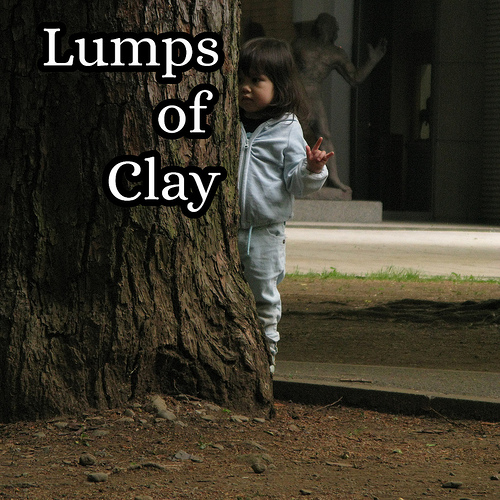

Lumps of Clay – excerpt thumbnail

Image by andrewtoskin

a photo comic

words by Andrew Toskin writing as Niccolo Florence

photography by hikaru starr

People have been worrying as well significantly about ebola. How lengthy until you catch children?

Copyright 2014. This function is published beneath a Inventive Commons Attribution-NonCommercial-ShareAlike 4. International License. Which means fundamentally that you’re cost-free to copy and share this operate — provided you credit us as the supply — but not sell it. We are open to the thought of enabling commercial use, even though just ask us 1st. Reposts and remixes of this work should attribute Niccolo Florence and hikaru starr, and hyperlink to curefornightmares.com

Text and images were composited with GIMP. Complete-size JPEGs are here on Flickr.

You’ll also discover the present supply files, plus various exported file formats at

the Net Archive.

Here’s the original comic script:

Panel 1: HIK_4769 edit.JPG — silhouetted loved ones on the

beach, with pier and sunset.

@Title and Byline

> Lumps of Clay

words by Niccolo Florence

photography by hikaru starr

curefornightmares.com

caption: I am no one’s father. (However?)

Panel two: IMG_0587.jpg — intense close-up on infant Ema’s face.

caption: But unless or until I succumb, it is my duty

to warn you that *children are harmful.* Stay away

from them anytime feasible.

Panel 3: img_0811.jpg — Ema in a green hoodie in front of

one hundred dangling wooden placards.

caption: If you hear any friends or sexual partners talk about

how their “biological clocks are ticking,” leave the region

and wash your hands. If they *bring* any youngsters with them,

immediately evacuate all childless adults from the vicinity

and notify the nearby authorities.

Panel four: IMG_8976.jpg — Ema peeking around the bole of a

tree, with a creepy statue in the background.

caption: Most individuals are aware of the troubles young children

can trigger, but numerous do not realize the complete extent

of the danger, and so do not take sufficient

precautions. Fortunately, young children do come with a number

of warning indicators to ward off potential adult

caretakers.

Panel five: img_0276 roppongi edit.jpg — Ema’s face covered in red paint(?)

caption: Some of the better known examples consist of the

smells and noise…

Panel 6: HIK_1878.jpg — Ema standing on leading of a statue,

looking down at us.

caption: Less apparent issues: They are also

codependent, irrational, evil creatures, unable to

negotiate or delay gratification. Any individual who shares a

household with a child for extended will slave their days

away to slake ever-altering whims.

Panel 7: IMG_0452.jpg — Ema with a blue onesie more than her

head. Possibly the cutest in the set.

caption: Kids are precision engineered to brainwash

you into loving them.

Panel 8: DSC_4229.jpg — Ema operating to a seesaw in a park.

caption: They will break your things, and break the

bank, and break your dreams, but absolutely nothing is worse than

the techniques they break your heart.

Panel 9: HIK_4865.jpg — Ema seen through a kaleidoscope.

caption: Youngsters are the most insidious of parasites:

The longer they remain with you, the deeper their

tendrils grow into you, cinching your ribs tighter and

tighter around your lungs, slithering into your

nervous technique until you can scarcely believe about

anything else — and then they develop up and leave you.

Panel ten: HIK_0131.jpg — Ema at a shrine, pouring water

over one hand.

caption: And the hole they leave behind just bleeds and

bleeds…

Panel 11: HIK_9941.jpg — Ema wearing an auburn wig.

caption: This is the worst element of all, something that

even most in-individuals who have tested constructive for

children may not recognize for years.

Panel 12: HIK_9841.jpg — black and white Ema holding her

hand up to block the camera.

caption: Since you and your child will drive each

other crazy. *Someone’s* life is receiving ruined, and

you will be terrified that it will not be yours.

caption: You will get in a stupid fight about producing the bed or

some thing and you will both commence screaming and throwing

items, and next thing you know it hits me that I’m

becoming my mother, I’m perpetuating the cycle.

Panel 13: HIK_9310.jpg — Sick Ema in jacket and face mask.

caption: Kids are so fragile, so malleable. Soft

lumps of clay that mold to the contours of your hand

no matter how you try *not* to mold them.

caption: Right after all my blunders, will she be okay? Will

she grow up all proper?

Panel 14: IMG_0567.jpg — singer with guitar and mic.

caption: Could the way she sings in the bathroom be a

sign that she’ll grow up to be a musician?

Panel 15: IMG_8976.JPG — A dancer.

caption: A dancer?

Panel 16: _HIK8727_014-two.jpg — model leaning over glass and handrail.

Panel 17: HIK_5078 raw edit.JPG — kabuki(?) performer on stage.

caption: Some kind of artist, surely.

Panel 18: HIK_1095.jpg — Ema, facing away from the camera.

caption: …Will she be happy?

Panel 19: Huge, complete-page shot. HIK_5285.JPG — Mysterious portrait of Ema

in a hat and daisy dress at night, hunting straight into the camera.

caption: …She isn’t even my daughter. I’ve only met

her once. But I currently enjoy her so much it hurts. I

worry obtaining a youngster of my own would *destroy* me.

End.