Some cool milling and machining images:

Image from page 56 of “Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and complete grinding and bolting combined husk or portable flouring mills, portable corn and feed mills; smut and separating machines; zigzag and

Image by Internet Archive Book Images

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and complete grinding and bolting combined husk or portable flouring mills, portable corn and feed mills; smut and separating machines; zigzag and oat separators, dustless separators, warehouse separators, water wheels; mill shafting; pulleys; spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Works. [from old catalog]

Subjects: Nordyke, Marmon & Company Flour industry Milling machinery Mills and mill-work

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

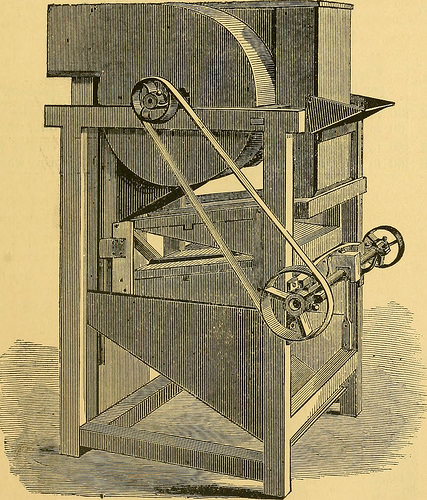

ank, will be required. TABLE OF DIMENSIOKS. No S o Height fromwhere wheat en-ters to floor. SIZE ON FLOOR. 1^ DIAMETER OFPULLEY. Height from Floor to Centre of Pulley. CAPACITY PER HOUR. 0 5 ft 5 in. 4 ft 2 ft 2 in. 700 6 in-4inface 1 foot. 10 to 15 bu 1 6 ft 2 In. 5 ft 6 in. 2 ft 2 in. 700 7 in-1 in face 1 foot. 20 to 30 bu 2 6 ft 10 in 6 ft 2 in. 2 ft 8 in. 625 10 in-5 in face 1 foot 2 in. 40 to 60 bu 3 7 ft 6 in. .5 ItOin. 3 ft 1 in. 550 14 in-6 in face 1 foot 4 in. 100 to 125 bu £ 2 3 7 ft 8 in. 5 ft 2 in. 2 ft 8 in. 650 10 in-5 in face 1 footlin. 40 to 60 bu & 3 7 ft 11 in 5 ft 3 in. 3ft2in. 550 14 in-6 in face 1 footl in. 100 to 125 bu 8 ft 2 in. 5 ft 6 in. 3 ft 6 in. 500 14tol6in-8inface 1 footl in. 125 to 150 bu ^ 5 3 I 8 ft 2 in. 5 ft 4 in. 3 ft 9 in. 450 18to24in-8inface 1 foot 4 in. 175 to 2001 bu RICHMOND MILL FURNISHING WORKS. 45 DUSTLESS OAT SEPARATOR AND ZIGZAG. With two or four Wheat Riddles and Cockle Riddle. j^ATENTED ^PRIL 9, 1861; JIe-ISSUED, A.PRIL 1 9, 187I.

Text Appearing After Image:

This China Machine is named Dustless Separator, because theDust is separated from the wheat, conveyed out of the mill, anddeposited in a dust room, before the grain passes to the riddles; thewheat and screenings are left free from dust. 7 46 RICHMOND MILL FURNISHING WORKS. Its operation is as follows:—The grain enters the China Machine at thehopper, which is shown, where it receives the first blast; then passesthrough two to four wheat riddles in succession, and over a cockleriddle into the second blast. The riddles deposit oats, sticks, weeds,ergot, rat-balls, etc., in suitable spouts; the heavy screenings fall intoa hopper and are spouted off. This China Machine has none but suctionblasts, and is offered to the milling community as a first-class Separa-tor. Dimensions and Capacity. No. Capacityper hour. Size onfloor. Extreme -n nHeight. P«y- Kev. perminute. 23 30 to 40 bush.60 to 80 bush. 30 to 40 bush.60 to 80 bush. 33x3445x34 33x3445x34, 5 ft. 4 in 5 ft. 5 in 6 ft. 2 in6 ft. 3 in 6 in.6 in. 4404

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Image from page 27 of “Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and complete grinding and bolting combined husk or portable flouring mills, portable corn and feed mills; smut and separating machines; zigzag and

Image by Internet Archive Book Images

Identifier: descriptivepamph00rich

Title: Descriptive pamphlet of the Richmond Mill Furnishing Works: all sizes of mill stones and complete grinding and bolting combined husk or portable flouring mills, portable corn and feed mills; smut and separating machines; zigzag and oat separators, dustless separators, warehouse separators, water wheels; mill shafting; pulleys; spur and bevel, iron and core, gearing ..

Year: 1873 (1870s)

Authors: Richmond Mill Furnishing Works. [from old catalog]

Subjects: Nordyke, Marmon & Company Flour industry Milling machinery Mills and mill-work

Publisher: Richmond, Ind., Telegram Steam Print. Co.

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

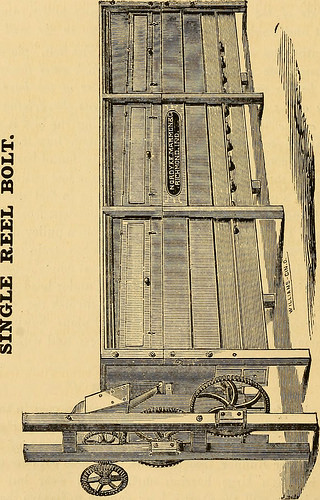

convenience. Wehave it shown in a small way in the cut, Fig. 3, under head of Com-plete China Grinding and Bolting Mills. Where we furnish the mills, wealways, when requested to do so, send draft and plans showing how toset up and arrange all, so that it will be a success, and without addi-tional charge. GEARED MILLS Are furnished with wood and iron gearing—wooden cogs in the driv-ing wheel. This does away with the noise and deafening clatter ofthe ordinary, or all iron geared mills. (See under head of Gear-ing, and Under Runner Geared Mills.) These cogs are of wideface, thus having a large bearing surface, and wear but slowly.Where there is one mill the shaft is long enough to receive the pulleyand one journal box outside. We often put three run of burrs,two wheat and one corn, upon one continuous shaft. This makes avery compact arrangement. In this case the mills are detached byslipping the pinion or wheel out of gear, on a sleeve provided for thepurpose. 20 DESCRIPTIVE PAMPHLET OF THE

Text Appearing After Image:

o > § a > c RICHMOND MILL FURNISHING WORKS. 21 SINGLE REEL BOLT—Complete, and Dimen-sions. (See preceding page.) Our bolts are so well known that a full description seems superflu-ous. Their constant use for fourteen years has suggested some markedchanges, which together with aWief outline of the bolt itself, we willdescribe. The object gained is a more efficient bolt for custom work,either for a Portable Mill or any flouring mill however large or small,where a bolt is wanted specially adapted to the demands of customgrinding; at the same time a bolt that can be shipped to any point ona navigable river or railroad in the United States or Territories. Wehave already sent a number of them into Northern Minnesota andWisconsin. Also, Texas, Kansas, Georgia. &c., &c. When so or-dered they are taken apart and boxed, previously marked how eachpart belongs, and drafts and description of how to set it up, sent sothat one at all skilled can put it up in the mill and have it rea

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.