5-axis milling is fundamentally a technique by which materials can be reduce. Employing this equipment, a rotating cutter can be moved via space to a discrete make contact with point on a work piece and cut with any discrete plane on the milling cutter. In order to accomplish this cutting approach, only 5-axix mill of motion are needed to accomplish this whereas, extra axes are redundant.

In USA, at present there are a lot more than 15 original equipment manufacturers of 5-axis machining centers. The value variety of 5 axis mill machine centers vary from USD 500,000 to more than USD 1,500,000. Even so, there are much less pricey 5-axis machining centers on the marketplace these days have a starting price tag of about USD 250,000. In current years, there are myriads of firms that have currently begun providing a committed 5-axix mill machining center that is basically a tilting rotary table that is integrated into the table of the mill. A lot of a occasions, there is a rotary table only, and the spindle delivers the tilting capacity. Even though there are some limitations when it comes to size and weight, these hybrid machines are also extremely costly.

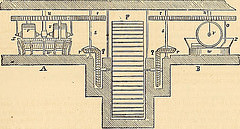

In both vertical and horizontal five-axis milling, there are two added axes that are added to the current X, Y and Z axes. These two axes are generally a rotary axis that rotates around the Z axis and a tilting axis that rotates about the other two axes, i.e. Y or Z axes. At the moment, there are 3 main methods of reaching simultaneous five-axis milling. The techniques are as provided under:

• A devoted five-axis machining center

• A tilting/rotary or trunnion table

• A spindle head attachment

The methods used to achieve simultaneous five-axis milling in different industries as aerospace, energy production, oil and gas, health-related, woodworking and mold-producing are related nonetheless, every single business has certain applications and requirements that figure out how a given manufacturer gets the job accomplished.

MDA Precision is a expanding family owned organization that is committed to offering only highest good quality benchtop machining products and service. We specialize in the following solution lines: Benchtop CNC Mills, Benchtop CNC Lathes, Benchtop Manual Mills, Benchtop Manual Lathes and Benchtop 5-Axis Mill systems and Trunnians.

Far more three Axis Milling Machine Articles