Style is a matter of balance amongst weight and strength, cost and high quality, speed and accuracy. Prototyping is an crucial component of the designing procedure and presents the designer with multiple selections.

In plastic item design and style, technology has offered different prototyping options.

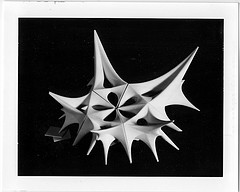

Rapid prototyping (RP) entails stereolithography, selective laser sintering, fused deposition modeling, laminated object manufacturing, and 3 dimensional printing. These processes construct components, 1-by-a single, from 3D-CAD models, joining layers of material to produce the finished prototype.

Speedy tooling (RT) makes use of fast prototyping to develop the initial part and then creates, from that portion, a mold in which added parts can be created.

An additional prototyping alternative is rapid injection molding (RIM), which performs straight from a 3D-CAD model, making use of CNC mechanism to crush aluminum molds in which correct injection-molded components can be produced. Finally, there is conventional injection molding, which is utilised mainly for production, but can also be utilized to create prototypes.

Style Prototyping UK is now a specialized sector that seamlessly works to provide the most recent and most sophisticated technologies for best plastic products to the firms in United Kingdom.

A Item Style Consultancy functions to create functional, mechanical and ergonomic model for any new solution style project. In deciding on plastic prototyping techniques, they provide you with greatest alternative, keeping in mind both technical and organization constraints. There are a variety of style consultancies for plastic item industrial design and style UK. They offer you with all prototyping alternatives:

* If shape and fit are your standard needs, fast prototyping and rapid tooling possibilities will function for you

* If you require parts for any functional testing, injection molding is a much better method than rapid prototyping

* If your requirement for number of parts is significantly less than ten, rapid prototyping would be an economical choice. If however number of parts required ranges amongst 10 to one hundred, then fast tooling or speedy injection molding could be greater option. Indeed speedy injection molding is the ideal decision if more than one hundred parts are required

For organizations in UK that have innovative product suggestions but just lack technical know how or have limited encounter in R&D, the best option is to pick a product design and style consultancy. Becoming specialists in the field of Style Prototyping UK, they give you the essential support for total designing of all elements including sophisticated assembly machines and special objective gear.

If you are searching for a ideal resolution for plastic solution designs, Detektdesign is the spot for you! We are knowledgeable designers & makers of plastic products and have helped many entrepreneurs via Design Prototyping UK, Solution Industrial Design UK.

Item Style China Company & International Product Style Consultancy: Dektekt design and style is a reputed Plastic product design company. DetektDesign provide Product Style Service, Style Prototyping UK. We are western owned item design and style consultancy that operates in the biggest manufacturing region in the globe.

Discover Much more China Prototyping Articles