Zhengzhou, China (PRWEB) September 02, 2014

Lately iAbrasive released an write-up on its official site. The report is about abrasives grinding wheel installation, balance and dressing. (See the original report at: http://www.iabrasive.com/articles/abrasives-grinding-wheel-installation-balance-and-dressing)

1. Installation

Particular interest ought to be paid when installing an abrasives grinding wheel on a grinding machine. Given that an abrasives grinding wheel works beneath a higher-speed rotation, we need to meticulously verify it ahead of using it to avert cracks. The abrasives grinding wheel have to be firmly installed in case of personal injury or a top quality accident.

The space between the internal hole of a grinding wheel and grinding wheel spindle can neither be also tense nor too loose. Normally, the space is .1–.eight mm for a high speed grinding wheel, the space can be smaller sized. When we use flange plates to set up a grinding wheel, the two flange plates’ diameter should be the identical, and its outer diameter must be no significantly less than a single-third of the grinding wheel’s thick cardboard’s outer diameter. To make the pressure uniformly distributed, thick cardboard or oil resistant eraser ought to be employed as a backing pad among flange plates and the finish face of the grinding wheel. In addition to that, the threaded fastener’s rotation path must be the opposite to that of the abrasives grinding wheel to make it fastened tightly.

2. Balance

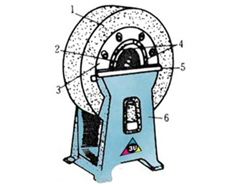

Usually abrasives grinding wheels whose diameter are longer than 125mm need to be balanced to make its center of gravity coincide with its spin axis. An unbalanced grinding wheel will vibrate during high-speed rotation, which has a undesirable influence on surface top quality or machine accuracy. The elements that lead to unbalance are the uneven distributions of density, asymmetry and installation eccentricity. Abrasives grinding wheel balance falls to two varieties: static balance and dynamic balance. Typically we need to only have static balance, but in higher-speed rotation (the speed is more quickly than 50m/s), dynamic balance is important. The following image shows an abrasives grinding wheel’s static balance installation: (1. grinding wheel two. spindle three. flange plate 4. counterbalance five. stable orbit 6. balancing stand).

When balancing, firstly we require to set up the grinding wheel onto the balancing axle, then lay it on the balance guide the grinding wheel will swing back and forth until it stops. At this time, we can move the balance block to make it balanced. A balanced grinding wheel can keep nevertheless in any location. If the abrasives grinding wheel is unbalanced, then the heavier components will rotate at the bottom. We can move the unbalanced block to make it balanced. A balanced abrasives grinding wheel must be checked for cracks ahead of it is installed onto the principal axis of a grinding machine. We should spot a .5–1 unit resilient sleeper-bearing among the grinding wheel and the flange plates. Normally the length diameter length of the flange plates is half of the grinding wheel’s diameter.

3. Dressing

Abrasive grains on an abrasives grinding wheel will turn into dull throughout the grinding approach or when dealing with ductile materials, abrasive dust always impacts in between the holes on the abrasives grinding wheel’s surface, which make it block and shed cutting potential. In this way, slip phenomenon occurs amongst the abrasives grinding wheel and the workpiece, which could result in vibration and noise. The grinding effect declines and surface roughness get weak. At the very same time, with grinding force and grinding heat enhance, workpiece deformation and grinding precision will be influenced. Apart from, due to uneven grinding wheel hardness and various operating situations of abrasive grains, grinding wheel functioning surface abrasion is not even, which affects workpiece shape precision and roughness. For that reason the abrasives grinding wheel needs dressing. The abrasives wheel is normally dressed by diamond, which has ultra high hardness and abrasive resistance.

For far more data, please visit: http://www.iabrasive.com/.