A few nice precision engineering photos I located:

Collet Holder Morse Taper

Image by tudedude

View On Black

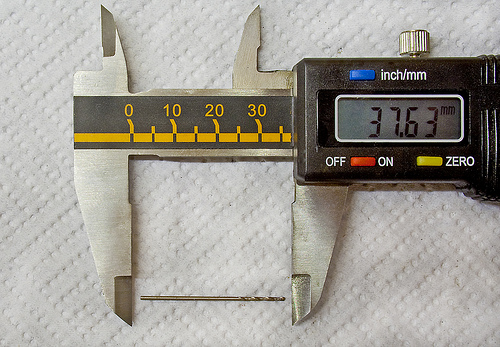

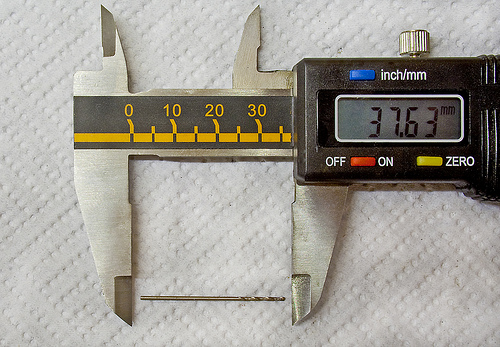

Just a Tiny Drill

Image by tudedude

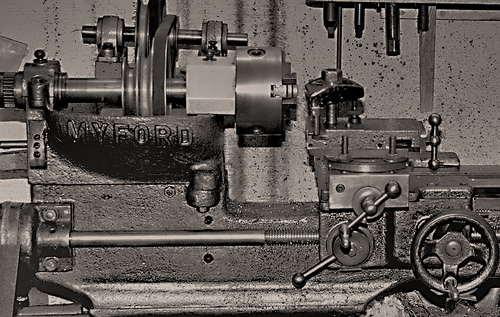

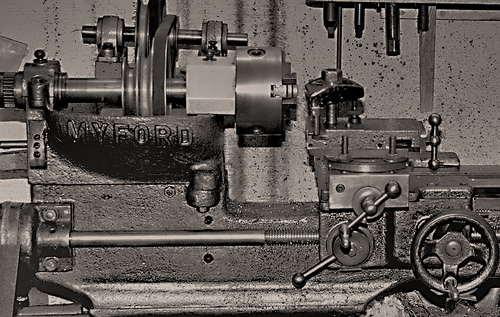

Old Metal functioning Lathe

Image by tudedude

Rapid Prototyping China

A few nice precision engineering photos I located:

Collet Holder Morse Taper

Image by tudedude

View On Black

Just a Tiny Drill

Image by tudedude

Old Metal functioning Lathe

Image by tudedude

A couple of nice precision engineering components images I found:

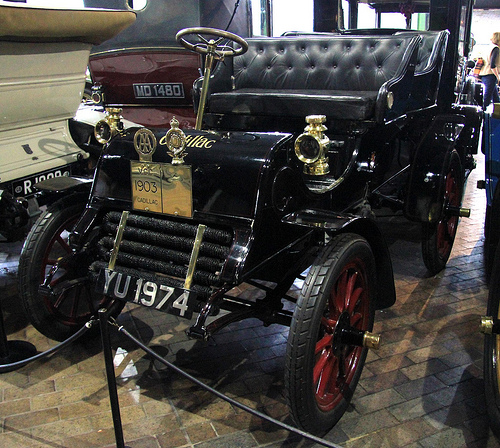

Beaulieu National Motor Museum 18-09-2012

Image by Karen Roe

1903 Cadillac

USA

This Model A was the initial Cadillac to be brought to Britain. Frederick Stanley Bennett imported it and drove it in the 1903 Thousand Miles Trial. Bennett subsequently became the official UK importer and was behind the standardisation tests of 1908 in which three identical Cadillacs were dismantled and then rebuilt from a mixed up pile of components, proving the interchangeability of the elements.

Produced in 1902 by Henry Leland, Cadillac was constructed upon the remains of the original Henry Ford Firm. From the starting Leland insisted on the highest requirements of precision engineering in order to build a quality mass produced car, demanding that ‘We need to make every piston so precise and every single cylinder so exact that every piston will fit into every cylinder’. Regardless of these higher production requirements more than 2000 Cadillacs had been developed in 1903.

Engine: 1609cc, 1 cylinder, overhead valve, six,5hp

Performance: 30mph

Cost New: £200

Manufacturer: Cadillac Automobile Business, Detroit

Owner: Mr J.F. Bennett and Mrs M Southam

Housing a collection of over 250 automobiles and motorcycles telling the story of motoring on the roads of Britain from the dawn of motoring to the present day, the award winning (Winner – The International Historic Motoring Awards of the Year 2012) National Motor Museum appeals to all age groups. From World Land Speed Record Breakers such as Campbell’s famous Bluebird to film favourites such as the magical flying car, Chitty Chitty Bang Bang and uncommon oddities like the giant orange on wheels. Don’t miss fascinating extra attributes such as the Motorsport Gallery, Wheels and Jack Tucker’s Garage – A permanent, multi award-winning 1930’s garage has been produced inside the Museum, comprehensive down to the final nut and bolt and rusty drainpipe. While the building is a comprehensive fabrication, everything in it – all the fixtures, fittings, tools and ephemera – are genuine artefacts collected over a period of 25 years.

Custom Inshore Snook Spinning Rod

Image by Cajun Custom Rods

This Cajun Custom Rods™ “Inshore Snook Spinning Rod" is functionality-enhanced and hand-crafted to provide you the quite greatest custom fishing rod obtainable – loaded for inshore fishing action! Precision-tuned for energy-finesse inshore spin-casting, this custom fishing rod leverages cutting-edge technologies to incorporate: a classic layout of hand-tuned Titanium REC Recoil spinning guides with "Spring-Back technology," a CCR™ split grip manage technique utilizing Super Grade Premium Higher Density (HD) Portuguese cork, a sensitivity-tuned and ergonomic AERO spinning reel seat (silver hood / comfort finish), ProWrap "Metallic Green & Black" thread, and a laser-cut Snook decal. This custom fishing rod is built around a perfectly engineered 7′ Lamiglas inshore popping series rod blank … engineered, fabricated, and hand-tuned to each premium component! Custom-made, corrosion-proof, and strike-prepared … At Cajun Custom Rods™, you style the rod of your dreams and we’ll build your self-assurance!”

"Tight Wraps, Tight Lines, and Content Fishing on the 4th of July!"

– Jaesen Yerger

Cajun Custom Rods™, Inc.

www.cajuncustomrods.com

Custom Inshore Snook Spinning Rod

Image by Cajun Custom Rods

This Cajun Custom Rods™ “Inshore Snook Spinning Rod" is efficiency-enhanced and hand-crafted to supply you the extremely greatest custom fishing rod available – loaded for inshore fishing action! Precision-tuned for power-finesse inshore spin-casting, this custom fishing rod leverages cutting-edge technologies to include: a standard layout of hand-tuned Titanium REC Recoil spinning guides with "Spring-Back technology," a CCR™ split grip manage program utilizing Super Grade Premium High Density (HD) Portuguese cork, a sensitivity-tuned and ergonomic AERO spinning reel seat (silver hood / comfort finish), ProWrap "Metallic Green & Black" thread, and a laser-cut Snook decal. This custom fishing rod is constructed around a completely engineered 7′ Lamiglas inshore popping series rod blank … engineered, fabricated, and hand-tuned to every single premium element! Custom-developed, corrosion-proof, and strike-ready … At Cajun Custom Rods™, you design the rod of your dreams and we’ll create your self-assurance!”

"Tight Wraps, Tight Lines, and Content Fishing on the 4th of July!"

– Jaesen Yerger

Cajun Custom Rods™, Inc.

www.cajuncustomrods.com

Award-Winning EMS Provider, Creation Technologies, Seems on Fox Business …

… including complete-service manufacturing facilities, two turnkey product improvement centers, and two NPI centers for fast prototyping. The firm also has facilities in Canada, Mexico and China. On August 13th, Marvel Production Group, LLC (MPG …

Study a lot more on GlobeNewswire (press release)

Sophisticated filament is important to 3D printing revolution

… holds them collectively." I thought about that story the other day for the duration of a telephone contact with Xiaofan Luo, founder of the Chinese company Polymaker, which makes filament for 3D printers. polymax-engine.jpg … The team figured that 3D printing — then …

Read more on ZDNet

Boy With Severely Deformed 'Porcelain Legs' Sees His Life Saved by 3D Printing

Just ask a six-year-old tiny boy in China, named Komine, who was born with a condition effecting about a single in 20,000 newborns, known as Osteogenesis Imperfecta (also recognized as “brittle bone disease” or Lobstein Syndrome). If you thought breaking a bone …

Read a lot more on 3DPrint.com

Petalite bids to raise £300k to launch rapid smartphone charger

Twelve component companies located in France, the US, China and Thailand have also been sourced, with the initial 1,100 Petalite batteries scheduled for delivery in October. Leigh Purnell, founder and inventor of Petalite, mentioned: "Portable batteries …

Study more on Birmingham Post

The scary history and future of Brazil's booming drone market place

Sánchez says a single cause for Brazil's speedy ascension in the drone revolution can be located in the history of the military dictatorship. Military rulers built on Brazil's currently … For many UAV businesses, like American ones, the BRIC countries …

Read more on Fusion

LeapFrog: 12 ideas for India to seize the digital entrepreneurship opportunity

3 waves of digital innovation have swept across India over the past decades: the software services boom of the 1980s, the DotCom boom of the late 1990s, and the a lot more current wave powered by SMAC technologies (social, mobile, analytics, cloud).

Study far more on YourStory.com

British hydrogen fuel cell pioneer develops automobiles and iPhones of the future

Indian mobile masts are the foundation of Winand's strategy for fast expansion. The scale of the rollout will provide … Manufacturing tens of thousands of fuel cells will bring expenses down and attract much more buyers, says Lawson-Statham, who joined the …

Study far more on Telegraph.co.uk

New Possibilities in the .2 Billion Conductive Ink Market place

The target industry here is speedy prototyping or low volume manufacture of boards with 4 layers or higher (etching PCBs gets a lot more difficult with growing layer numbers). This strategy seeks to reduce prototyping turnaround time for multi-layer circuits …

Study much more on EE Instances

How A Philosophy Of "Informed Creativity" Drives Design and style At Map

But right here's the kicker: it expenses just $ 150—a fraction of what you'd spend for an Apple laptop—and it's so easy to build that youngsters can do it. The cleverness and user-friendliness at the heart of …. Fast iteration is essential for Map and its consumers …

Read more on Co.Design

Unusual 11 Mid-Day Movers eight/21: (MCUR) (SPIL) (NWY) Greater (TUES) (CCIH …

Siliconware Precision Industries Co., Ltd. (Nasdaq: SPIL) 23.7% Larger Advanced Semiconductor Engineering announced nowadays that it plans to commence on August 24, 2015, tender delivers in the Republic of China and the United States for common shares …

Read much more on StreetInsider.com

Deals of the day- Mergers and acquisitions

Taiwan's Advanced Semiconductor Engineering Inc (ASE) on Friday stated it would get up to 25 % of Siliconware Precision Industries Co Ltd (SPIL) for an amount likely exceeding T$ 30 billion ($ 918.98 million). ** The planet's largest oil trader Vitol …

Study a lot more on Reuters

Flextronics International Director Lay Koon Tan Sells 2798 Shares (FLEX)

The Business delivers a variety of design and style and engineering solutions that relate to manufacturing (which includes enclosures, metals, plastic injection molding, precision plastics, machining, and mechanicals), technique integration and assembly and test solutions, …

Read more on Dakota Economic News

Some cool high precision engineering photos:

Image from page 1147 of “Electrical globe” (1883)

Image by World wide web Archive Book Images

Identifier: electricalworld43newy

Title: Electrical planet

Year: 1883 (1880s)

Authors:

Subjects: Electrical engineering

Publisher: [New York McGraw-Hill Pub. Co., etc.]

Contributing Library: Engineering – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Pictures From Book

Click right here to view book on-line to see this illustration in context in a browseable on the web version of this book.

Text Appearing Prior to Image:

or belt ordirect connection rotary converters, motor-generator sets, oil-in-sulated and air-blast transformers, direct-present and alternating-existing railway motors and controllers, single and polyphase in-duction motors of constant and variable speeds, direct-current motorsof several kinds, including motors for variable-speed service fromsingle and double-voltage circuits, switchboard apparatus, ammeters,voltmeters, wattmeters, synchroscopes, energy factor meters, circuit-breakers and switches, a lot of of them electrically operated portableinstruments, instruments of precision, potential regulators, and innu-merable other forms of auxiliary apparatus and instruments. Thealternating-existing, series-wound, single-phase crane motors, sim-ilar in sort and common construction to the single-phase railwaymotors exhibited in the Transportation Building, and the new West-inghouse Unit Switch System of Numerous Control are also to heseen in this section. The spectacular high-tension sign, utilizing a

Text Appearing After Image:

FIG. five.—BRAKE E.XHIBITS, TRANSPORTATION Developing. brake which is now so considerably in use. The method at present gen-erally adopted when two pumps are used on 1 locomotive isshown, and a single of the novel attributes of the rack is that all valvesare placed ig duplicate, a single sectioned so as to show the internalworking mechanism, and connected to the valve in use in such a ELECTRICAL Planet and ENGINEER. Vol. XLIII, No. 24. manner that it moves as the standard valve is operated. The opera-tion of the different valves is therefore readily studied. The Westinghouse friction draft gear also is shown in section,with a machine specially made for testing it in operation. Theavailable power which can be e.xerted on the draft gear approximates2,000 pounds. A triple valve testing rack is presented to show themanner in which this device is now getting installed in a lot of rail-road shops. Sectional parts also are shown of the other apparatusof the Westinghouse Air Brake Organization and the WestinghouseTraction Brake

Note About Photos

Please note that these photos are extracted from scanned page photos that may have been digitally enhanced for readability – coloration and look of these illustrations may possibly not perfectly resemble the original function.

Product style and development is the term that encompasses the improvement, designing and manufacturing of the item. The methodologies have changed but the goal is still the identical. The modify of techniques has created this field a lot a lot more dependable and strong. Throughout the emerging days of this sector the solution designing was carried out through hand produced drawing and the prototypes that had been generated lacked accuracy.

Even although they lack accuracy and reliability, the item designing services were extremely costly and only huge players in the market place were in a position to avail this service. But with the building technology the accuracy and reliability of the generated prototype has improved and the expense of availing the service also becomes cheaper. Therefore, the new technologies for solution prototyping led to the much more dependable and precise solutions and at a very reasonable price tag.

One of the main benchmarks in the field of Item Prototyping was the introduction of Fast Prototyping tools such as Autodesk. The Autodesk application helped the designers to create a digital prototype of the solution and test the generated prototype also. With the improved version of this software it even inherits the feature to generate the 3D prototype of the solution defining the measurements and functions of each and every part.

Then with the establishing era of Solution Designing Solutions there came an additional key achievement of 3D printing Prototyping. With the support of this technology the item can be visualized like a reside item. The generated prototypes of the solution have the same appear and feel as that of the original product. The 3D Model Printer is used to produce the models for the product employing the model printers. The solution design and improvement industries all more than the globe have adapted these newest prototyping services and these who are still stuck to the old approaches are facing a great reduction in their clientele.

Unlike the earlier prototyping technique, these Rapid Prototyping strategies have created the perform simpler for solution improvement. When handmade styles had been employed, accuracy factor was significantly missing in many of the prototypes as a outcome of which the development group employed to work upon the accuracy and they have to operate for both developing the product as properly as to eradicate the errors.

These most current prototyping tactics have created it less difficult for designers to inherit accuracy in the generated prototype as nicely as they can test the prototype too which increases the level of accuracy and make the solution prototype fairly reputable for designers, client and improvement team.

WB Engineering was established in fall 2007, since then has been growing year after year by increasing its capabilities and consumer base. Our staff consists of engineers with varying backgrounds, which includes Biomedical, Mechanical and Electrical Engineering. With in home capabilities for digital and fast prototyping using the newest and most sought after technologies

How Indra Nooyi Turned Style Pondering Into Strategy: An Interview with …

In China, we've introduced a stacked chip that comes in a plastic tray inside a canister. When a lady desires to snack, she can open her … When I image style pondering, I think about speedy prototyping and testing. Is that component of what you're trying …

Study more on blogs.hbr.org (blog)

A few nice precision engineering companies images I found:

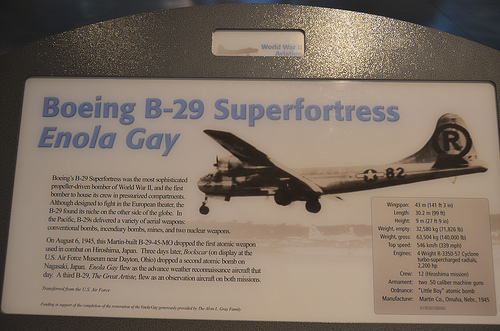

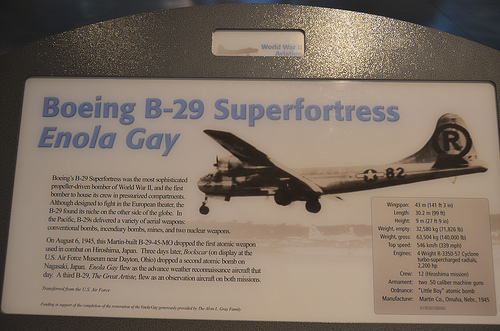

Steven F. Udvar-Hazy Center: B-29 Superfortress “Enola Gay” caption

Image by Chris Devers

See more photos of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of World War II and the first bomber to house its crew in pressurized compartments. Although designed to fight in the European theater, the B-29 found its niche on the other side of the globe. In the Pacific, B-29s delivered a variety of aerial weapons: conventional bombs, incendiary bombs, mines, and two nuclear weapons.

On August 6, 1945, this Martin-built B-29-45-MO dropped the first atomic weapon used in combat on Hiroshima, Japan. Three days later, Bockscar (on display at the U.S. Air Force Museum near Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on both missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

Overall: 900 x 3020cm, 32580kg, 4300cm (29ft 6 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Materials:

Polished overall aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and high-aspect ratio wings. Polished aluminum finish overall, standard late-World War II Army Air Forces insignia on wings and aft fuselage and serial number on vertical fin; 509th Composite Group markings painted in black; "Enola Gay" in black, block letters on lower left nose.

Long Description:

Boeing’s B-29 Superfortress was the most sophisticated, propeller-driven, bomber to fly during World War II, and the first bomber to house its crew in pressurized compartments. Boeing installed very advanced armament, propulsion, and avionics systems into the Superfortress. During the war in the Pacific Theater, the B-29 delivered the first nuclear weapons used in combat. On August 6, 1945, Colonel Paul W. Tibbets, Jr., in command of the Superfortress Enola Gay, dropped a highly enriched uranium, explosion-type, "gun-fired," atomic bomb on Hiroshima, Japan. Three days later, Major Charles W. Sweeney piloted the B-29 Bockscar and dropped a highly enriched plutonium, implosion-type atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. On August 14, 1945, the Japanese accepted Allied terms for unconditional surrender.

In the late 1930s, U. S. Army Air Corps leaders recognized the need for very long-range bombers that exceeded the performance of the B-17 Flying Fortress. Several years of preliminary studies paralleled a continuous fight against those who saw limited utility in developing such an expensive and unproven aircraft but the Air Corps issued a requirement for the new bomber in February 1940. It described an airplane that could carry a maximum bomb load of 909 kg (2,000 lb) at a speed of 644 kph (400 mph) a distance of at least 8,050 km (5,000 miles). Boeing, Consolidated, Douglas, and Lockheed responded with design proposals. The Army was impressed with the Boeing design and issued a contract for two flyable prototypes in September 1940. In April 1941, the Army issued another contract for 250 aircraft plus spare parts equivalent to another 25 bombers, eight months before Pearl Harbor and nearly a year-and-a-half before the first Superfortress would fly.

Among the design’s innovations was a long, narrow, high-aspect ratio wing equipped with large Fowler-type flaps. This wing design allowed the B-29 to fly very fast at high altitudes but maintained comfortable handling characteristics during takeoff and landing. More revolutionary was the size and sophistication of the pressurized sections of the fuselage: the flight deck forward of the wing, the gunner’s compartment aft of the wing, and the tail gunner’s station. For the crew, flying at extreme altitudes became much more comfortable as pressure and temperature could be regulated. To protect the Superfortress, Boeing designed a remote-controlled, defensive weapons system. Engineers placed five gun turrets on the fuselage: a turret above and behind the cockpit that housed two .50 caliber machine guns (four guns in later versions), and another turret aft near the vertical tail equipped with two machine guns; plus two more turrets beneath the fuselage, each equipped with two .50 caliber guns. One of these turrets fired from behind the nose gear and the other hung further back near the tail. Another two .50 caliber machine guns and a 20-mm cannon (in early versions of the B-29) were fitted in the tail beneath the rudder. Gunners operated these turrets by remote control–a true innovation. They aimed the guns using computerized sights, and each gunner could take control of two or more turrets to concentrate firepower on a single target.

Boeing also equipped the B-29 with advanced radar equipment and avionics. Depending on the type of mission, a B-29 carried the AN/APQ-13 or AN/APQ-7 Eagle radar system to aid bombing and navigation. These systems were accurate enough to permit bombing through cloud layers that completely obscured the target. The B-29B was equipped with the AN/APG-15B airborne radar gun sighting system mounted in the tail, insuring accurate defense against enemy fighters attacking at night. B-29s also routinely carried as many as twenty different types of radios and navigation devices.

The first XB-29 took off at Boeing Field in Seattle on September 21, 1942. By the end of the year the second aircraft was ready for flight. Fourteen service-test YB-29s followed as production began to accelerate. Building this advanced bomber required massive logistics. Boeing built new B-29 plants at Renton, Washington, and Wichita, Kansas, while Bell built a new plant at Marietta, Georgia, and Martin built one in Omaha, Nebraska. Both Curtiss-Wright and the Dodge automobile company vastly expanded their manufacturing capacity to build the bomber’s powerful and complex Curtiss-Wright R-3350 turbo supercharged engines. The program required thousands of sub-contractors but with extraordinary effort, it all came together, despite major teething problems. By April 1944, the first operational B-29s of the newly formed 20th Air Force began to touch down on dusty airfields in India. By May, 130 B-29s were operational. In June, 1944, less than two years after the initial flight of the XB-29, the U. S. Army Air Forces (AAF) flew its first B-29 combat mission against targets in Bangkok, Thailand. This mission (longest of the war to date) called for 100 B-29s but only 80 reached the target area. The AAF lost no aircraft to enemy action but bombing results were mediocre. The first bombing mission against the Japanese main islands since Lt. Col. "Jimmy" Doolittle’s raid against Tokyo in April 1942, occurred on June 15, again with poor results. This was also the first mission launched from airbases in China.

With the fall of Saipan, Tinian, and Guam in the Mariana Islands chain in August 1944, the AAF acquired airbases that lay several hundred miles closer to mainland Japan. Late in 1944, the AAF moved the XXI Bomber Command, flying B-29s, to the Marianas and the unit began bombing Japan in December. However, they employed high-altitude, precision, bombing tactics that yielded poor results. The high altitude winds were so strong that bombing computers could not compensate and the weather was so poor that rarely was visual target acquisition possible at high altitudes. In March 1945, Major General Curtis E. LeMay ordered the group to abandon these tactics and strike instead at night, from low altitude, using incendiary bombs. These firebombing raids, carried out by hundreds of B-29s, devastated much of Japan’s industrial and economic infrastructure. Yet Japan fought on. Late in 1944, AAF leaders selected the Martin assembly line to produce a squadron of B-29s codenamed SILVERPLATE. Martin modified these Superfortresses by removing all gun turrets except for the tail position, removing armor plate, installing Curtiss electric propellers, and modifying the bomb bay to accommodate either the "Fat Man" or "Little Boy" versions of the atomic bomb. The AAF assigned 15 Silverplate ships to the 509th Composite Group commanded by Colonel Paul Tibbets. As the Group Commander, Tibbets had no specific aircraft assigned to him as did the mission pilots. He was entitled to fly any aircraft at any time. He named the B-29 that he flew on 6 August Enola Gay after his mother. In the early morning hours, just prior to the August 6th mission, Tibbets had a young Army Air Forces maintenance man, Private Nelson Miller, paint the name just under the pilot’s window.

Enola Gay is a model B-29-45-MO, serial number 44-86292. The AAF accepted this aircraft on June 14, 1945, from the Martin plant at Omaha (Located at what is today Offut AFB near Bellevue), Nebraska. After the war, Army Air Forces crews flew the airplane during the Operation Crossroads atomic test program in the Pacific, although it dropped no nuclear devices during these tests, and then delivered it to Davis-Monthan Army Airfield, Arizona, for storage. Later, the U. S. Air Force flew the bomber to Park Ridge, Illinois, then transferred it to the Smithsonian Institution on July 4, 1949. Although in Smithsonian custody, the aircraft remained stored at Pyote Air Force Base, Texas, between January 1952 and December 1953. The airplane’s last flight ended on December 2 when the Enola Gay touched down at Andrews Air Force Base, Maryland. The bomber remained at Andrews in outdoor storage until August 1960. By then, concerned about the bomber deteriorating outdoors, the Smithsonian sent collections staff to disassemble the Superfortress and move it indoors to the Paul E. Garber Facility in Suitland, Maryland.

The staff at Garber began working to preserve and restore Enola Gay in December 1984. This was the largest restoration project ever undertaken at the National Air and Space Museum and the specialists anticipated the work would require from seven to nine years to complete. The project actually lasted nearly two decades and, when completed, had taken approximately 300,000 work-hours to complete. The B-29 is now displayed at the National Air and Space Museum, Steven F. Udvar-Hazy Center.