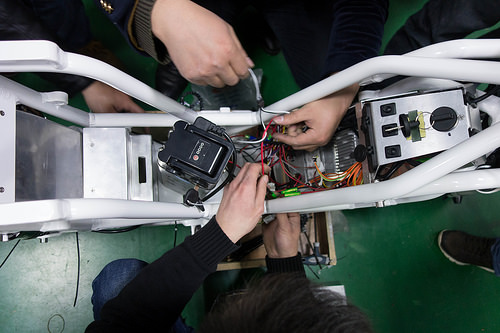

Some cool prototype china images:

Ubco Assembly

Image by locusresearch

2×2 in assambly, China 2015

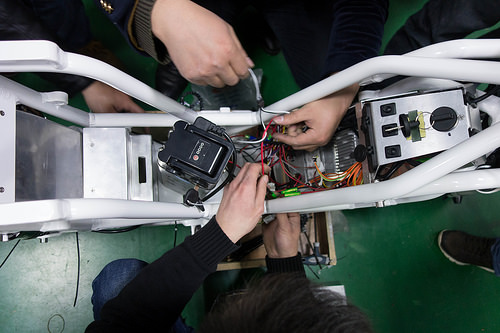

Ubco Assembly

Image by locusresearch

2×2 in assambly, China 2015

Ubco Assembly

Image by locusresearch

2×2 in assambly, China 2015

Rapid Prototyping China

Some cool prototype china images:

Ubco Assembly

Image by locusresearch

2×2 in assambly, China 2015

Ubco Assembly

Image by locusresearch

2×2 in assambly, China 2015

Ubco Assembly

Image by locusresearch

2×2 in assambly, China 2015

Meet the Marshall London: Amp Maker Introduces Phone for Music Lovers …

The London is an Android Lollipop phone custom-fitted for music lovers, with a processor for high-resolution audio (like uncompressed FLAC files), headphone jacks constructed into it, Marshall Mode earbuds, a button that fires up the phone's music UI, a …

Read more on Guitar World Magazine

A Glimpse at Autodesk's Robotics Lab of the Future > ENGINEERING.com

They are also functioning on software program that will enable Castor and Pollux, two of their robots, to work in simultaneous collaboration with higher precision. Even though commercial adoption of these developments are not extensively available but, the lab's integration of …

Read far more on ENGINEERING.com

Inkjet printing equipment for organic LED mass production | SPIE Newsroom: SPIE

Inkjet was a logical candidate since this technology can deliver hugely scalable, pattern-smart precision deposition of organic thin films with high material efficiency. Generating inkjet successful, nevertheless, requires very good inkjet gear and excellent …

Read far more on SPIE Newsroom

Sponsored: Open supply SDN brings “build- it” culture to life

Since these new interfaces assistance quick prototyping models and simple configuration, they are driving a “build it” culture exactly where coders create and test items in a fairly short period of time. This is in sharp contrast to prior solution …

Study a lot more on RCR Wireless News

The Legacy of Satoru Iwata :: Games :: Lists :: Paste

In the late ྖs, Kirby creator Masahiro Sakurai started prototyping an idea for a sumo game, tentatively titled Dragon King. … Saito and Iwata became quickly close friends and would collude on tips that, in Saito's mind, by no means genuinely went anywhere. In one particular …

Read much more on Paste Magazine

Regional Motors prepares three-D vehicle production

Most main automakers have already been making use of 3-D printing in the prototyping phase for years. Toyota, for example, has been making use of 3-D printing for speedy prototyping at its North American operations for practically 20 years, Toyota spokesman Brian Watkins said.

Read far more on Automotive News

CNC Turning Center

Image by spangineer

A little CNC turning center, in the Leonhard Constructing at Penn State.

MassMEP and UMass Lowell to Expand Training in Massachusetts

The Sophisticated CNC Instruction Program is a manufacturing certification system that adds value and merit to the sector to encourage men and women to contemplate careers in manufacturing. The program also creates a regular instruction set and constantly …

Study more on UMass Lowell (press release)

Beauty on the inside – Slowtwitch.com

It would not surprise me if the same cutting machine we utilised for wetsuits is utilised for cutting carbon fiber out of a sheet (although these can also be reduce by CNC machines, the patterns programmed in, and alternatively of blades the reduce may be carried out by water …

Study far more on Slowtwitch

Wood that wows: Partisan's Bar Raval is a ravalation

I wasn't going to write about Bar Raval, created by Partisans, till I had been in a position to go there and see it. Even so it is so well-liked that it is difficult to get in, and it just won the AIA R&D award, so I am writing it now, even although I know it shouldn't …

Study a lot more on Treehugger

Action Star Donnie Yen Reportedly Joins 'Episode VIII' Cast

According to an post on Singapore-primarily based newspaper The Straits Times, which cites a Hong Kong newspaper referred to as Apple Daily, the film has cast Hong Kong action icon Donnie Yen in the film as “a Chinese Jedi.” Yen's character … Possibly the biggest …

Read much more on Dork Side of the Force

Chinese elements in Hollywood films

Kung fu superstar Bruce Lee was maybe the very first Chinese face Hollywood familiarised itself with. Action stars Jackie Chan, Chow Yun-fat and Jet Lee followed his footsteps, but for a long period of time, it seemed like all Chinese actors who got roles …

Read more on Telegraph.co.uk

The go-to junior for a tightening zinc market place

About 17% of zinc demand comes from zinc-based alloys that support the die casting business. From bathroom … What we do know is that China desires to reduce its pollution issues, but to what extent this work slows down mining is anyone's guess …

Read far more on MiningFeeds.com

Munich, Germany (PRWEB)

July 09, 2015

Nanopositioning specialist PI (Physik Instrumente) L.P., a leader and resolution provider in motion handle and positioning components and systems, releases its newest product line catalog on Air Bearing stages. The new brochure on US-made and manufactured precision positioning equipment was introduced at this year’s “LASER Globe of PHOTONICS” – one particular of the world’s top international trade shows and conferences for the laser and photonics industry – in Munich, Germany.

Why Air Bearings

Air-bearings have no rolling or sliding components and provide completely frictionless, non-contact motion, resulting in negligible hysteresis or reversal error, better straightness, flatness and velocity stability, which are ideal prerequisites for higher-finish industrial inspection and manufacturing operations. Air bearing stages are ideally suited for many high precision applications, such as metrology, photonics alignment, semiconductor, flat panel show, precision scanning applications, and cleanroom applications.

Watch Video Animation

> How Does Air Bearing Technology Function?

Nanometer precision and multi-axis motion stages made with the highest straightness / flatness are the hallmarks of PI’s normal and custom created air bearing options. The PI group develops and manufactures all air bearing products at their Hopkinton, MA and Milford, NH facilities.

Download PIglide Air Bearing Technology Catalog

> Learn far more

Regular and Custom

PI has in-home engineered solutions from over four decades of experience functioning with customers to offer a common product or to modify current item styles to match the precise specifications of the application with a custom resolution.

Applications of PIglide Air Bearing Technologies

Applications contain metrology, photonics alignment, semiconductor, flat panel show, precision scanning applications, cleanroom applications.

About PI

PI is a leading manufacturer of precision motion manage gear, piezo motors, air bearing stages and hexapod parallel-kinematics for semiconductor applications, photonics, bio-nano-technologies and healthcare engineering. PI has been developing and manufacturing common & custom precision goods with piezoceramic and electromagnetic drives for 4 decades. The organization has been ISO 9001 certified given that 1994 and supplies innovative, higher-quality solutions for OEM and analysis. PI is present worldwide with eleven subsidiaries, R&D / engineering on 3 continents and total staff of 800+.

USA / Canada

East

(508) 832-3456

Midwest

(508) 832-3456

West

(949) 679-9191 (LA Region & Mexico)

(408) 533-0973 (Silicon Valley/Bay Area)

PI (Physik Instrumente) L.P. l 16 Albert Street l Auburn, MA 01501 l http://www.pi-usa.us l info(at)pi-usa.us

Dexter, MI (PRWEB)

July 14, 2015

Recognizing the worth of providing each subtractive manufacturing and additive manufacturing (3D printing) in tending to the ongoing wants of its customer base, Protomatic announces the providing of 3D metal printed components to complement its existing supplying of precision machining services.

Additive manufacturing technologies fabricate parts, straight utilizing CAD data, by expanding layer upon layer of the selected material. Supplies that can be employed span a wide variety from plastics by means of metals. Additive manufacturing gives many strategic gains by means of the evolution of style through to production. These incorporate design and style freedoms for constructing complex attributes, both internal and external the potential to “grow” multiple iterations simultaneously and the capability to create functional parts for each testing and end-use applications. It also serves as a viable bridge amongst prototyping and production, to close the chasm of lead time until receipt of final casted components.

Not only does Protomatic recognize the significance of 3D printing, so does jet-propulsion giant Rolls-Royce. Speaking on 3D printing, Alan Newby, Rolls-Royce chief engineer for future applications and technologies says, “It is ideal for prototyping. Shortening the manufacturing time by almost a third gives us more time to design, which is usually a benefit. We are also capable to create styles we wouldn’t otherwise be in a position to do.”

Along with time savings, 3D printing also supplies cost savings. According to Pratt & Whitney President David Hess, “Additive manufacturing has enormous benefits from a cost standpoint. It also eliminates the time required to develop tooling.” In that regard, the additive process offered P&W up to 15 months lead time savings in establishing prototypes compared to standard manufacturing processes.

Protomatic has partnered with a shop that currently utilizes fourteen 3D metal printing machines, with aggressive plans to add many much more. Material offerings incorporate aluminum, titanium, stainless steel, Inconel, cobalt chrome and maraging steel. The partnership will serve a multitude of markets such as aerospace, power/oil, medical, automotive, industrial goods, and other people. Several markets are currently applying the technology to each prototype and production, recognizing that additive manufacturing has the capability to revolutionize every industry.

Already, the FDA is approving healthcare devices made via additive technologies. Just lately, the FAA authorized the very first 3D printed metal element to fly in a commercial jet engine from GE. The development and application of additive manufacturing (3D printing) is imminent. Protomatic is committed to life-saving precision in solutions that will carry its clients from concept by means of production.

###

Protomatic is a CNC precision machining shop specializing in prototype and short-run-production elements for the health-related, aerospace and other technical industries. Due to the fact of the vital nature of the components they design and style and manufacture, the emphasis is usually on Life-Saving Precision.

Premier metal fabrication organizations develop and manufacture products and systems in metal for industrial firms on a international scale. If your business needs fabrication services, you can rely on the sector leaders in this field. You get quality and sophisticated solutions that are of the most recent requirements at competitive rates.

The Process

Metal fabrication is usually applied to the business of developing metal and structures. Sheet metal is metal formed into thin flat pieces, which can be reduce and formed into a lot of shapes. The thickness of the metal is known as its gauge. Metal of different sorts which includes aluminum, brass and steel is cut, shaped, welded and polished in this process.

Top Organizations

Best sheet metal fabrication organizations have the knowledge, experience and capabilities required to meet the needs of large and tiny companies alike. State-of-the-art gear and technology of the most advanced level, is utilised to give highest quality solutions to customers. With two decades of experience they have the capability to serve a range of industrial demands in numerous sectors.

High degrees of skill and precision and thorough understanding of metal operating are crucial requirements, to satisfy clients’ demands. Custom fabrication processes are carried out to clients’ specifications and specifications. There are a lot of processes carried out which are comprehensive and elaborate in information according to each and every project.

A variety of Techniques Of Fabrication

Piercing through all materials is feasible making use of latest technologies such as laser cutting machines, water jet cutting machines and turret punching machines. Metal stamping, robotic welding are some of the processes utilized for metal fabrication techniques.

Some items require shearing, punching and bending and this is accomplished via a energy press machine. Sheet metal bending is carried out with gear that reduces costs and improves accuracy of complex bends. Panel bending is also carried out by means of specialized equipment that is useful for element consolidation and re-styles.

Plate rolling is one more technique of fabrication which makes it possible for a selection of components to be fabricated. The machine that carries out this operation has the capability for roll-segments, cylinders and multi-radius components. CNC punching is done for up to 200 tons and punching capacity of 55 tons and in addition extended gang punch applications to thirty feet. Press brake forming is one more method utilized in fabrication solutions to manage challenging multi-bend elements.

Metal fabrication requires a lot of detailed processes including

* Preparing top quality unprocessed metal

* Assembling of components into semi-completed or finished equipment

* Fitting and welding pieces into assemblies

* Machine pieces and assemblies into tolerance and surface finish

* Shop preparation and painting

Metal fabrication services presented by top firms in the field have consumer satisfaction and loyalty as their aim. They focus their services on understanding their customer’s wants and supplying custom requirements and good quality in service. Manufacturing flexibility and worth for money gives customers the ideal buying experience. Established knowledge ensures high production fabrications, which helps you, conceptualize and style your sheet metal merchandise. Certified engineers will assist you from concept to completion of your project.

Panelsandpipes.com is leaders in the sector of metal fabrication and sheet metal fabrication services. They focus their services on understanding their customer’s demands and delivering custom wants and quality in service.

Associated Sheet Metal Fabrication China Articles

Engineering components, in principle, may be divided into four main classes:

Metals

Ceramics and glasses

Polymers and elastomers

Composites

Supplies belonging to a single of these classes exhibit comparable properties, processing routes, and most typically applications as well. The criteria for the material choice are rather complex and depend on the intended application goal. To the principal design and style criteria belong strength, stiffness, fracture toughness, formability, capability to join, corrosion resistance, and coefficient of thermal expansion, price, and final but not least the capacity to recycle.

Iron-primarily based materials are the most widely employed metallic materials, primarily simply because of their comparatively affordable manufacturing and their massive flexibility. Accordingly, the properties of Fe-primarily based components can be varied to a great extent, allowing precise adaptation to particular application specifications ranging from higher-strength, high-temperature, and put on-resistant alloys for tools to soft or hard ferromagnetic alloys for applications in the electrical industries. Pure iron, even so, is only of minor significance in structural applications given that its mechanical properties are just inadequate. Alloying with carbon leads to the most crucial groups of constructional alloys, namely:

1. Steels with a carbon content material of up to about 2.06% carbon (if not stated otherwise all compositions are giving in wt. %)

2. Cast iron, which virtually consists of 2.5–5% carbon.

Ceramic and glass materials are complex compounds and solid options containing metallic and nonmetallic components, which are composed either by ionic or covalent bonds. Standard properties of glasses and ceramics include high hardness, high compressive strength, high brittleness, higher melting point, and low electrical and thermal conductivity. There are several methods in which ceramics may possibly be classified, such as by chemical composition, properties or applications. Polymers (polymer components, polymeric components, strong polymers, and macromolecular materials) consist of quite massive molecules (chain molecules, macro molecules) which are synthesized from little molecules (monomers, monomer units) by a chemical reaction named polymerization. The polymerization reactions can be classified into four groups. Chain polymerization proceeds by the reaction of a monomer unit with the reactive website at the finish of a polymer chain. These are mainly reactions by way of a radical mechanism. The terminus condensation chain polymerization is utilized in circumstances exactly where a low-molar-mass byproduct is formed during polymerization. In polycondensation currently generated polymer chains react with each and every other or with a monomer unit whereby a low-molar-mass byproduct is generated. Elastomers (rubber-like polymers) consist, similarly to thermoplastics, of linear molecules, but the molecule chains are bridged by modest-molecule segments via covalent bondings. The molecules can therefore undergo a robust elastic deformation at area temperature. This effect is due to the stretching of the molecules out of the disordered state if a load is applied, and a re-deformation into the random tangle of molecules due to the enhanced entropy, right after the load is released. Composite supplies are formed when two supplies which belong to various material classes are combined to attain properties which are not supplied by the original components. Achievable combinations are:

Metal–ceramics

Metal–polymer

Ceramic–polymer

For assistance with your Mechanical Engineering Homework Aid you can pay a visit to classof1.com

Classof1.com is open 24/7. You can get in touch with us at 1-877-252-7763 or drop an email to finding out@classof1.com

Discover Much more China Mechanical Engineering Articles

Steel workers have been an crucial element of the country’s economy since the industrial revolution. Steel is a major element of most buildings and other structures. Steel is an important element for creating structures and foundations as properly as for structures like bridges and other people. For an individual to turn into a steel worker it requires a higher level of education of the steel fabrication approach due to the fact it can be a dangerous job.

Steel fabrication has been a portion of the construction world considering that the 17th century but turn out to be much far more typical and accessible to builders with the development of the Bessemer procedure in the 19th century. Given that then, steel is one particular of the most widespread components employed when building a building or other structure, especially 1 that will be tall and needs a lot more support. Far more than 1.3 billion tons of steel is manufactured every year. Steel is a widespread element in buildings, infrastructures, tools, machines, boats, cars and trucks, weapons and appliances. The steel industry is frequently noticed as an indicator of the economy. When steel fabrication increases, it is normally observed as a sign of economic improvement due to the fact the more steel is necessary then the far more developing and constructing is occurring.

In some types of steel fabrication it is combined with other metals to kind alloys that are employed to make other things. Some of the most typical pairings is steel and manganese, chromium, nickel, tungsten and cobalt. These can be mixed by steel fabricators to either make the steel weaker or stronger, based on what it is utilized for. For instance, a surgical tool would need to be created of weaker steel so that it can be much more effortlessly bent into shape and it would then be lightweight sufficient to be simply employed by the surgeon. For surfaces that require to maintain their hard edge, stronger steel would be necessary. This would apply to issues like bulldozer blades, tank tracks and the cutters on the Jaws of Life.

Steel fabrication is frequently lumped together with iron production but the two are very distinct. The steel business has seen a decline in that previous handful of years because of the economy. The quantity of steel fabricators in the early 2000s was listed at 224,000 which was over half significantly less than the high of 500,000 fabricators in the 1980s.

Go to http://www.gsmindustrial.com for more information with regards to why this company is one of the top steel fabricators in the planet. As one of the premier steel fabrication companies, GSM Industrial continues to supply its consumers with solutions that meet and exceed expectations.

Discover More Steel Fabrication China Articles