Chicago, IL (PRWEB) September 17, 2014

When your vision is to be the major international resource for packaging and processing, and your mission is to increase and market members’ abilities to succeed in a global marketplace calling in a worldwide futurist like Jack Uldrich to talk about the newest technologies that will influence you and your future is wise point to do. And that is precisely what the Packaging Machine Makers Institute is doing on September 17th.

Founded in 1933, PMMI is a trade association produced up of far more than 650 member firms that manufacture packaging, processing and packaging-connected converting machinery, commercially-offered packaging machinery elements, containers and supplies in the United States, Canada and Mexico.

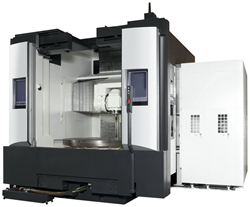

PMMI members are globally renowned for producing the highest quality gear, supplying responsive service and committing to meeting their customers’ demands. To that finish, being on the cutting of edge of technologies is crucial, and Jack Uldrich, as a futurist has his finger on the pulse of the technologies that PMMI needs to be watching for and using in the coming years.

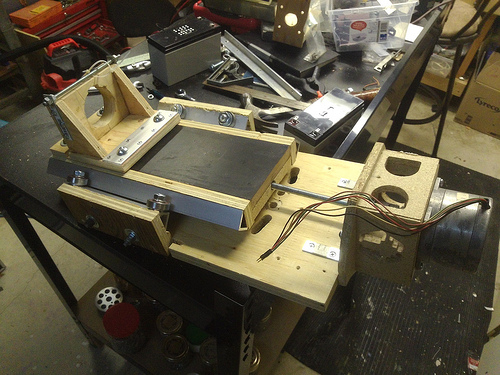

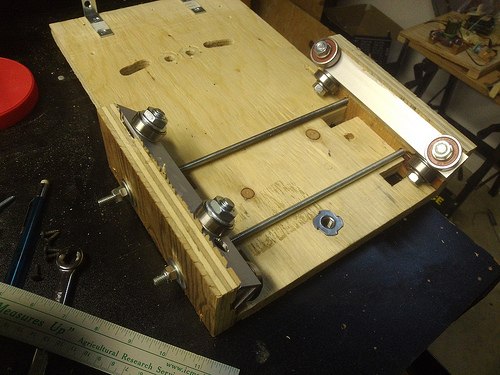

Amongst the ten technologies that Uldrich will go over with the PMMI group are things like the new Leap Motion manage (hand gesture technologies,) sophisticated 3D manufacturing tactics which might effectively transform and revolutionize the future of manufacturing, as nicely as sophisticated robotics which are currently offering a healthful advantage in the production of a lot of packaging and manufacturing materials.

When it comes to the future of manufacturing Uldrich says, “5 years ago, a 3D printer—a device that can manufacture physical objects—cost $ 100,000. Right now, equivalent printers are available for $ 1,000 and are poised to revolutionize the planet of manufacturing. What will the globe of tomorrow look like? The time to begin thinking about this is now.”

The Author of “The Next Large Issue is Genuinely Modest: How Nanotechnology Will Adjust the Future of Your Business” Uldrich will also address how nanotechnology will transform the manufacturing industry in the coming years.

Uldrich says, “In the coming year, packaging leaders can also expect to hear much more about the “Internet of Items.” In its simplest kind, the thought is that in the coming decade an estimated 50 billion physical objects will be connected to the World wide web by way of low-expense, wireless sensors. What tends to make the technologies so potentially revolutionary is that some of the sensors will be nano-barcodes that can authenticate merchandise (such as worthwhile pharmaceutical drugs) or nano-sensors that can study a host of info, which includes temperature, humidity and the level of exposure to oxygen, and then relay this info to companies, distributors and consumers to offer a comprehensive history of the item.”

Uldrich who speaks all more than the globe on a range of subjects such as future trends, emerging technologies, innovation, change management and leadership, is also a major professional on assisting firms unlearn and adapt throughout times of transition. He has served as an adviser to Fortune 1000 firms and is noted for his ability to deliver provocative, new perspectives on competitive benefit, organizational adjust and transformational leadership.

Parties interested in studying a lot more about him, his books, his day-to-day blog or his speaking availability are encouraged to visit his site. Media wishing to know a lot more about either the occasion or interviewing Jack as a futurist or trend specialist can make contact with Amy Tomczyk at (651) 343.0660.

Find Much more Precision Element Makers Press Releases