Los Angeles, CA (PRWEB) September 17, 2014

Brush Research Manufacturing (BRM), global supplier of Flex-Hone® tools and NamPower nylon abrasive brushes, is announcing the completion of a productive week-lengthy exhibit at IMTS 2014, America’s biggest manufacturing event and one particular of the world’s biggest industrial tradeshows. From September eight to 13, the BRM technical group showcased Flex-Hone® and NamPower technology at Chicago’s McCormick Spot.

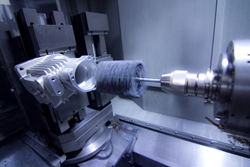

As visitors to the BRM Booth at IMTS 2014 learned, versatile honing tools help makers to enhance portion top quality and consistency. By enhancing surface finish and removing burrs at the same instances, flexible hones also assist industry to increase efficiency and enhance productivity. “It was a great show,” mentioned Heather Jones, Vice President of Marketing and advertising. “We had some fantastic conversations with manufacturers.”

How Manufacturers Use Flexible Honing Tools

As a follow-up to IMTS, BRM has published a technical report named How Makers Use Versatile Honing Tools that explains why Flex-Hone® tools are the sector standard for inner diameter (ID) applications. Self-centering, self-aligning to the bore, and self-compensating for put on, flexible hones get rid of cut, torn, and folded metal even though imparting a plateau finish for optimum lubrication.

Identified also as ball hones, Flex-Hone® tools feature abrasive globules that are permanently laminated to versatile nylon filaments. These surface finishing and deburring tools are also built with a double-wire metal mounting stem. Makers can use flexible cylinder hones during machine tool applications (on-line), or for the duration of secondary operations (off-line).

On-Line and Off-Line Operations

As BRM’s technical report explains, versatile hones mount in most machine spindles. Examples incorporate drill presses, lathes, milling machines, robotic cells, transfer lines, and CNC equipment. For off-line use, these cylinder honing tools can be utilised with a handheld power tool such as an electric drill. Regardless of how they are utilized, Flex-Hone® tools always demand the use of a high-high quality lubricant.

Flexible hones are used in both general industrial and specialized manufacturing applications. They come in ten various abrasive varieties, 11 grit sizes, and in regular diameters ranging from four-mm to 36”. For difficult materials such as ceramics, carbides, and aerospace alloys, BRM supplies the Diamond Flex-Hone® with its fast cut rates and self-sharpening, resin-bonded crystals.

For far more information about Flex-Hone® technology, download the Flex-Hone® Resource Guide.

About Brush Analysis Manufacturing

Brush Research Manufacturing (BRM), makers of versatile honing tools and a complete line of industrial brushes, is situated in Los Angeles, California. For more than 55 years, BRM has been solving surface finishing challenges with brushing technology. BRM’s Flex-Hone® tool is the industry standard against which all other ID surface finishing solutions are compared. Pick NamPower brushes for OD applications.

Media Speak to:

Heather Jones

Vice President of Advertising and marketing

Brush Analysis Manufacturing Co. Inc.

4642 Floral Drive

Los Angeles, CA 90022

HJones(at)brushresearch(dot)com

For Quick Release:

http://www.brushresearch.com/

Ph: (323) 261-2193