Just some pictures of a year long restore of a Bridgeport (step pulley) milling machine. The develop diary (which consists of detailed information on the processes, pain…

Video Rating: four / five

Rapid Prototyping China

Just some pictures of a year long restore of a Bridgeport (step pulley) milling machine. The develop diary (which consists of detailed information on the processes, pain…

Video Rating: four / five

Shanghai, China (PRWEB) August 29, 2014

P&A International, a die casting China primarily based company, has just announced that is has joined forces with a leading aftermarket and race car components designer and manufacturer to create higher end tuning solutions for Subaru racing teams. As element of this collaboration, a leading Subaru WRX tuning organization is operating with P&A International in order to finalize the development and production of the extensive turbocharger upgrade kit for the 2016 Subaru STI and later WRX models.

As a firm spokesperson for P&A International explained, the business has been contracted to manufacture the cast aluminum intake manifold for the new boxer 4 cylinder two.0L and two.5L engines.

“The two. liter FA series flat four is derived from the Subaru Forester 2.0XT and is an superb candidate for energy upgrades,” the spokesperson explained, adding that the new intake manifold consists of intricate custom die casting and precision CNC machined parts that are place collectively to form variable intake manifold that will enhance engine volumetric efficiency to peak at two points: 2500 RPM and 6500 RPM.

“This is done via changing geometry of the intake tract identified as pulse tuning.”

The style that P&A International is operating on is focused on mild and large turbocharger upgrades where the 2500 RPM point is employed to assist with the turbocharger spool, bringing down the turbo spool threshold some 500 RPM, which also allows the engine to operate effectively in complete energy output close to redline in high demand scenarios.

“The assembly will consist of aviation grade aluminum intake with custom electronic handle module and an enlarged throttle valve,” the spokesperson stated, adding that there will be provisions at every single port for water-methanol injectors supplied by UK-based company Aquamist, as nicely as provisions for NOS.

“The very same intake manifold will be obtainable in carbon fibre for race applications but tuned for max VE at 4500 RPM and 8500 RPM.”

About P&A International:

P&A is a China based company formed in 2008 by partners with engineering backgrounds. The company’s primary focus is the manufacturing of talent and technologies intense parts and elements in China. Getting a tiny player in the market, the organization operates really hard to establish themselves by providing their clientele customized service, often going outdoors of their scope to assistance them. For much more info, please visit http://www.pa-international.com.au/index.php?option=com_content&view=article&id=128&Itemid=173

New Possibilities for Accuracy, Versatility in Cylindrical Grinding

Shigiya (USA) Ltd. is due to introduce a number of new series of universal and cylindrical grinders to the IMTS crowd in September, in diverse configurations and specifications to address the particular tasks that machine shops determine for higher-precision …

Read more on American Machinist

Shigiya Precision Gpes-30 Series Cnceccentric Pin / Polygon Grinder Attributes …

SHIGIYA (USA) LTD., the world-class manufacturer of cylindrical grinders, introduces its efficient and high accuracy GPES-30 Series of CNC Eccentric Pin / Polygon Grinders. Featuring a hugely rigid base and thermal expansion manage, the GPES-30 is …

Study far more on MFRTech (press release)

Some cool china machined parts images:

Big Sky

Image by Wootang01

15.five.09

We’re driving towards the orphanage. The highway is lonely, save for a couple of languid trucks ambling along. It is damp too, and a thick fog covers the countryside: a single light right here or there supplies the only hint of civilization amidst the interminable verdure. Inside the van, the smoke of cigarettes previous wafts in the air, lingering like a lost soul. I inhale, and quickly cough. I subsequently open the window to the enveloping darkness outside, so slightly as to not disturb my companions in the back. The roar of the road echoes in my ears.

An unexpected wrench was thrown into our travel plans nowadays. The trip began expediently sufficient as the bus on which Candy and I rode reached the Shenzhen airport with hours to spare even so, the unscheduled hiccups soon followed. We received an announcement more than the public address system notifying us of a flight delay, due to a mysterious military maneuver, we deduced, higher in the Shenzhen skies. Numerous a lot more sonorous reminders came in punctual succession more than the next six hours. It seemed as even though we would be stuck, stranded genuinely, at the airport forever, or for the day at least. Thankfully, following the police arrested some of the far more aggrieved passengers, we ultimately boarded the plane and took off for central China. We were blessed to be on our way at final, none of us getting blown a gasket during the afternoon tedium.

1 far more pitch black road awaited, down a single lonely lane lined with swarthy trees, standing as although sentries, and at length we arrived at the orphanage. The car stopped in a clearing, and we stepped out, onto a cement lot with soft puddles spread silently beneath our feet. We squinted into the twilight, our eyes trying to make sense of the surroundings. Our bags have been unloaded, we made our way to the rooms, and soon adequate fell asleep. I feel we all enjoyed the repose, rendered particularly comfortable by the new guest rooms in which we were staying.

16.five.09

We have only been here for barely 24 hours, yet it feels as though we have been here for significantly longer, as if time at some point in our journey decided to slow itself to a crawl. Maybe it was simply because of the litany of activities that we packed into the span of a number of hours, or perhaps it was the lack of worldly distractions, allowing us to focus solely on our mission, that brought on us to suspend the hands of that imaginary clock in our mind. Whatever the case, we’ve enjoyed each minute at the orphanage it is time undoubtedly effectively spent in service!

Morning get in touch with was at six:20 and soon after a prayer meeting we went down to lastly visit the kids. They had been playing on the vast driveway of the orphanage, savoring their moment of freedom ahead of breakfast. To see so many friendly faces, in spite of their precarious physical and filial circumstance was undoubtedly encouraging. I made a multitude of new buddies and did my best throughout the day to influence those little ones with joy, honesty and patience. It is a effective cocktail which brings adore quickly to many.

The food at the orphanage is without processing, as all-natural as victuals can be in these days of impersonal industrial production. Large chunks of mantou, steaming bowls of soupy congee, and salty vegetables with slivers of meat have characterized our meals. It is the kind of humble stuff that lengthens life spans, and disciplines the palate.

We presented a wide variety of activities – structured and unstructured entire class and small group – to the youngsters, in the hope that we would manage them as significantly as amuse. In the morning, as though breaking the ice when have been not adequate, we ran via a series of dizzying, if not at occasions entirely incoherent, activities developed to familiarize our dispositions to every other. Later, we established a makeshift entertaining fair, at which we ushered the kids to rooms filled with (board) games, and puzzles, and other, a lot more colorful activities such as face painting and balloon producing. The kids could not at length include their enthusiasm, busting into and out of rooms with impunity, soaking in the rapturous atmosphere. In the afternoon, our team attempted to tire them out: operating topped the agenda, and by leaps and bounds, the activities, regardless of whether simple relays or schoolyard classics like duck duck goose and red light, green light, indeed began to tucker our charges out. We, too, had been quite beat by the time night started to creep over the horizon!

17.5.09

Yesterday evening, we shocked the students with a musical overall performance, followed by forty minutes of bubble-blowing madness to be certain, the students could not appreciate our somewhat correct rendition of Remarkable Grace so considerably as the innocent madness of dipping one’s hands in a remedy of dish detergent and corn syrup and then whispering a bubble to life and indeed, the moment the Disney branded bubble-making machines churned the 1st batch of bubbles into the air, with significantly rapidity weaving their frenetic pattern of exciting, chaos erupted in the area. The students stormed the soap basin, and virtually overwhelmed my teammates who valiantly held the Snitch and Pooh higher above the heads of the clamoring little ones.

During the evening’s festivities, I grew progressively ill, till at last I dashed out of the space to sneeze. Outdoors, in the cool of the evening, below a cloud of stars beaming so far away in the deep of space, I exploded in a rancor of sneezing. The match lasted for five minutes, an inexorable depression in my method which sent each my body and my esteem tumbling down. I felt bad, not only for my exceedingly rickety wellness, but for my teammates and the youngsters who might have been exposed to my sickness as it incubated within me furthermore, everybody in the classroom was saying goodbye and all I could do was rid myself of a sniffle here and there, in amongst rounds of bursting from nostrils and sinuses. I was impotent, as although 1 of my insignificant droplets on the floor!

18.5.09

We are in a vehicle heading towards a renowned historical website in Henan. The driver’s drawl slips gradually from his mouth, and what he says resonates intelligibly in our ears. Candy, Tanya and the driver are discussing Chinese mythology, and history, which, for far better or for worse seem to be inextricably intertwined. We narrowly just now missed hitting an idle biker in the middle of the road in dodging our human obstacle, the auto swerved into the oncoming visitors, sending us flying inside the cabin. Reciting a verse from a worship song calmed our frazzled nerves.

How to describe the children? A lot of of them smiled freely, and had been so polite when greeted that undoubtedly they had been educated effectively at some point in the tumult of their life education. Precociousness was also a common characteristic shared by the little ones, whose stunted bodies belied the mature, perspicacious thoughts hiding just underneath the skin. Of course, in our time together we have been a lot more merry than severe, that good quality being very best left for the adults operating silently in their rooms and to that effect, the children brought out their funny bones and jangled them in the air to stir up the excitement and to destroy by a jocular clamor any hint of a dull moment – we genuinely laughed a lot. At final, though not all of them seemed interested in our staged activities – rather than feign enthusiasm and eagerness, some skipped our events altogether – these who did participate, most of them in fact, enjoyed themselves with abandon, assisting to generate that delightful atmosphere exactly where the a lot of sounds of elation reign.

Of the students whom I had the opportunity to know personally, a number of still stick out in my thoughts, not the least for my possessing christened a few of them with English names! David was bold, and courageous, willing to soothe crying babes as much as reprimand them when their capricious actions led them astray he had a caring heart not unlike a shepherd who tends to his young charges. Edward, who at 13 was the identical age as David, absolutely grew emotionally, not to mention physically attached to me. He was by my side for significantly of the weekend, grabbing onto my hand and not letting go, to the point where I in my arrogance would detach my fingers within his, ever so slightly, as if to suggest that a second a lot more would lead to a clean break – I know now that with the cruel hands of time motoring away during the mission, I should not have lapsed into such an independent, selfish state he ought to have been my son. An additional kid who became so attached to the group as to intimate annoyance was the boy we deemed John’s son, due to the fact the boy, it seemed, had handcuffed himself to our teammate, and would only free himself to trigger insidious mischief, which would invariably outcome in an explosion of hysterics, his eyes bursting with tears and his mouth, as wide as canyon, unleashing a sonorous wail when one thing went wrong. On the other hand, Alice remained in the distance, content material to smile and shyly wave her hand at our group even though hiding behind her sisters. And last but not least, of our precious goonies, Sunny undoubtedly was the photographer extraordinaire, usually in charge of the school’s camera, snapping away liberally, never enabling any passing moment to escape his shot.

That I discovered on this trip so considerably about my teammates verily shocked me, as I thought the relationships that we had established have been currently mature, not hiding any new bump, any sharp edge to surprise us from our friendly stupor. So, consider myself delightfully amazed at how a handful of slight alterations in the personality mix can bring out the best, the most inventive and the strangest in the group dynamic: admittedly, Candy and Tanya were the perfect foils for John, they eliciting the most humorous observations and reactions from my house church leader, they expertly constructing a depth of character that even final week, in the wake of the Guangdong biking trip, I by no means knew existed! Most of all, I am glad to have been a portion of such a harmonious fellowship, for the reality that we could prayer with each other as a single, and encourage each and every other also, and all the more as we saw the day approaching.

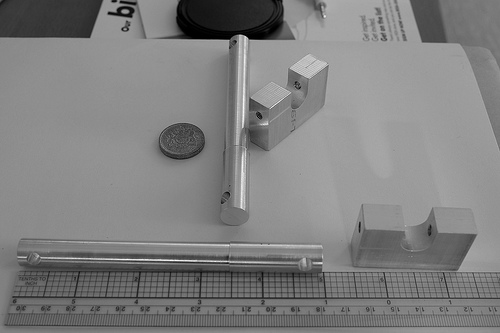

A couple of nice machined aluminum components photos I identified:

the prc!!

Image by Inha Leex Hale

is in the house.

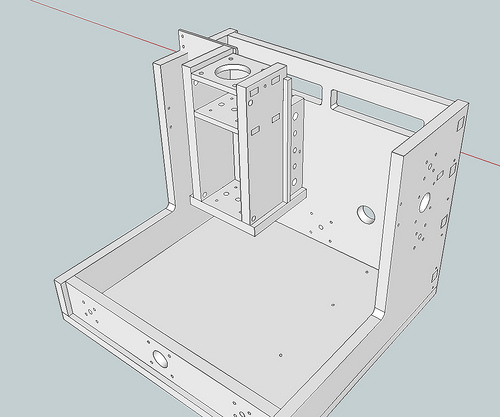

All Parts_Grey

Image by SignalPAD

Charlotte, NC (PRWEB) August 28, 2014

At IMTS 2014 Okuma will introduce its new LU4000 EX CNC lathe which utilizes two turrets, enabling two tools to work simultaneously, delivering approach flexibility as nicely as higher removal prices. This machine is outstanding for machining parts for the automotive business. At IMTS this machine will be shown cutting a camshaft utilizing Machining Navi for chatter reduction and tooling from Sandvik, a member of Partners in THINC.

The LU4000 EX incorporates a new 45° “box bed” with all box way construction, three point bearing assistance for the spindle, crown gear turret coupling for each turrets, two energy ranges and the Okuma THINC®-OSP control, offering a foundation for a long production life. This CNC lathe is Okuma’s most recent evolution of 4-axis turning in the ten-15” chuck class.

Important Functions of the LU4000 EX CNC Lathe

Max Turning Diameter: mm (in) Ø430 (Ø16.93) (upper turret)

Ø280 (Ø11.02) (decrease turret)

Spindle Nose Variety: A2-8

Main Spindle Speed Range: min⁻¹ 40~4,200

Milling Spindle Speed Range: min⁻¹ 45~6,000

X/Z Axis Travel: mm (in) 300 (11.81) / 740 (29.13) (upper turret)

195 (7.68) / 700 (27.56) (reduce turret)

Y Axis Travel: mm (in) 140[+/-70] (five.51[+/-two.76])

For far more info on Okuma’s LU4000 EX check out http://www.okuma.com/lu4000-ex and Okuma America Corporation booth S-8500 at IMTS 2014.

About Okuma America Corporation

Okuma America Corporation is the U.S.-primarily based sales and service affiliate of Okuma Corporation, a globe leader in CNC (personal computer numeric manage) machine tools, founded in 1898 in Nagoya, Japan. The business is the industry’s only single-source provider, with the CNC machine, drive, motors, encoders, spindle and CNC manage all manufactured by Okuma. Okuma’s innovative and reputable technology, paired with complete, localized service protection, permits customers to run continuously with self-assurance – maximizing profitability. Along with its sector-top distribution network (largest in the Americas), and Partners in THINC, Okuma facilitates top quality, productivity and efficiency, empowering the customer and enabling competitive advantage in today’s demanding manufacturing environment. For far more data, go to http://www.okuma.com or adhere to us on Facebook or Twitter @OkumaAmerica.

About Partners in THINC

Partners in THINC is a collaboration network of far more than 40 market leaders who come with each other to resolve difficulties and explore new productivity suggestions for genuine-globe producers. With the open architecture, Pc-based THINC®-OSP manage as its nucleus, Partners in THINC brings specialized equipment, experience and a commitment to give the best feasible integrated options to the finish-user. For a lot more data, visit http://www.okuma.com/partners-in-thinc.

###

Los Angeles, CA (PRWEB) August 13, 2014

Brush Study Manufacturing (BRM), Produced in USA supplier of Flex-Hone® tools, is announcing a new technical article and solution video about NamPower nylon abrasive wheel brushes. Accessible in silicon carbide and diamond abrasive filaments, NamPower wheel brushes function composite hubs, virtually indestructible cores, a balanced construction, and a option of face widths and diameters.

Constructed with a uniform fill pattern and larger filament densities, NamPower nylon abrasive composite hub wheels give an option to wire wheels and non-woven abrasive brushing tools. NamPower wheels are utilised in the production of turbine blades, steel gears, machine components, extrusion reduce-offs, and shaft finishing. These abrasive nylon radial brushes can also generate an edge radius on cutting tool inserts.

Diamond Wheel Brushes

As BRM’s new technical article explains, industrial purchasers should pick NamPower diamond filament wheel brushes for tougher components such as ceramic, glass, carbide, and hardened tool steels. These diamond abrasive wheels are also excellent for making edge radii on diamond and cubic boron nitride (CBN). Their composite hub building gives a dense, uniform fill pattern for far more cutting points.

NamPower diamond wheel brushes are also advised for polishing the flute relief on carbide and higher speed drills, end mills, and reamers. With end mills and reamers, a polished flute relief enhances chip removal and promotes greater finishing and longer tool life. NamPower diamond abrasive wheels are also utilised to make an edge radius on carbide inserts to avoid fracturing and premature wear.

For much more information about NamPower diamond abrasive wheel brushes, such as diameters, face widths, and accessible grit sizes, read BRM’s technical post or speak to sales(at)brushresearch(dot)com.

Silicon Carbide Wheel Brushes

As BRM’s new technical article explains, buyers can also pick NamPower wheel brushes with silicon carbide (SC) abrasive. Usually, these abrasive nylon wheels are recommended for use with other industrial metals, such as aluminum and steel. As with diamond wheel brushes, NamPower silicon carbide wheels feature a uniform fill pattern and greater filament density.

Grit selection is highly dependent on the starting surface finish and the quantity of material refinement that’s needed. Coarse grits are recommended for use on heavier burrs, or in applications where a fine surface finish is not necessary. Fine grit brush tools that are utilized on a rough starting finish will have much less impact on surface condition improvement than the use of a coarse-grit brush followed by a finer-grit tool.

For much more details about NamPower silicon carbide wheel brushes, download the NamPower Resource Guide.

About Brush Analysis Manufacturing

Brush Study Manufacturing (BRM), makers of flexible honing tools and a full line of industrial brushes, is positioned in Los Angeles, California. For over 55 years, BRM has been solving surface finishing challenges with brushing technology. BRM’s Flex-Hone® tool is the industry common against which all other surface finishing solutions are compared. Check out the BRM site to understand much more.

Media Speak to:

Heather Jones

Director of Advertising and marketing

Brush Investigation Manufacturing Co. Inc.

4642 Floral Drive

Los Angeles, CA 90022

HJones(at)brushresearch(dot)com

For Immediate Release:

http://www.brushresearch.com/

Ph: (323) 261-2193

Verify out these laser milling photos:

TinyG playing the Man On The Silver Mountain Song.

Image by rileyporter

Gcode File for the song available at:

www.thingiverse.com/point:3260

new mill test laser version

Image by rileyporter

Milling machines are machine tools which are utilized to machine strong components. There are two simple varieties of these machines and they are vertical milling machine and horizontal milling machine. The two distinct kinds are referred to horizontal and vertical due to the fact of the orientation of the primary spindle. Milling machines can vary in size from small bench mounted machines to considerably larger area sized machines. Milling machines operate by moving the workpiece around and against the cutter, and the sides of the cutter are utilised to cut material as nicely as the tip. The workpiece and cutter are very precisely controlled to thousandths of an inch ( .001 ). Milling machines could be mechanically automated, manually operated or pc numerically controlled ( CNC ). The manual operation of some varieties of precision engineering machine such as the lathe or milling machine are quite frequently controlled by computer or numerically controlled.

Numerical control or NC, or laptop numerical handle CNC refers to the automation of machine tools which are operated by programmed commands that are encoded on a storage medium.

Milling is a machining operation in which a workpiece is provided the desired shape by the action of a rotating cutter, whilst the workpiece performs linear movements. In its simplest form the milling cutter is a circular disc whose rim is offered with specially shaped teeth (cutting edges). The cutters are of a lot of distinct sorts and shapes. The operate is fed against the teeth of the cutter, even though the feed motion is longitudinal, transverse or vertical, based on the kind of milling machine and the nature of the operate. Milling machines are of the horizontal or vertical variety.

Right now numerous CNC milling machines are computer controlled vertical mills, and have the capacity to move the spindle vertically along the Z axis. In CNC milling and turning, end to finish element design and style is automated making use of CAD/CAM applications. The system is place into the lathe or milling machine and the machine is then ready for production. Some machined components will typically need a number of diverse tooling applications such as drilling, reaming and tapping and so on, and most modern machines will combine tools inside a single cell. This cell will move or rotate to apply the necessary tooling application, and this will also be controlled by the CNC system. With todays contemporary and complicated machines, the machined part or workpiece can be moved from machine to machine automatically with the use of pc controlled robots, or human intervention, but in either case the steps required to produce any portion is very automated and the finished element will closely match the CAD design.

CNC machines have been initial constructed in the 1940s and have been programmed by using paper tape with holes punched into it at certain points. These early systems have been soon overtaken with the augmentation of analogue and digital computers. There is a variety of CNC systems that can be fitted to previously manually operate machine tools, and these systems supply a selection of functions which can drastically improve the productivity of the machine and the top quality of the perform that is created.

Anthony Pateman from RD Castings Ltd writes about CNC Milling. For far more details about CNC Milling visit www.rdcastings.co.uk

Much more Milling Solutions Articles

BRASS PRECISION TURNED Components FOR ALL THE INDUSTRIES AS PER SPECIFICATIONS ELSE AS PER INTERNATIONAL Requirements SUCH AS DIN AND ALL OTHER. WE ARE AN ISO 9…

Video Rating: / 5

Kamal Metal Items http://kompass.in/kamal-metal-products an manufacture and export firm involve in Precision Brass Metal Components given that 1975, utilised fo…

Video Rating: / 5