Precision Screw Thread Corp. info @ http://www.precisionscrewthread.com . Linear motion/Power transmission specialist. PST specializes in thread rolling solu…

Video Rating: 4 / 5

Rapid Prototyping China

Precision Screw Thread Corp. info @ http://www.precisionscrewthread.com . Linear motion/Power transmission specialist. PST specializes in thread rolling solu…

Video Rating: 4 / 5

A few nice slot milling images I found:

Returns slots, Mill Park Library, Yarra Plenty Library service

Image by sirexkat

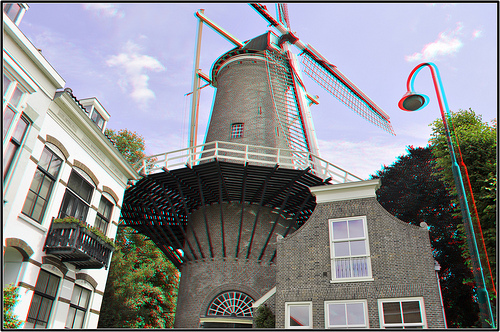

Molen ‘t Slot Gouda 3D

Image by wim hoppenbrouwers

anaglyph red/cyan

Slitting saw

Image by tudedude

Rebuild, Don't Replace

Welding, for example, requires China cutting out the broken or worn area, fixing a new block of steel, performing the welding and completely re-machining the insert. It also can involve additional steps such as China machining, polishing, testing, etc., … “In …

Read more on Modern China Machine Shop

Anaheim, Califrnia (PRWEB) August 18, 2014

M Line Holdings, Inc. (OTC PINK: MLHC; “M Line” or the “Company”), is a leading provider of products, assemblies and services to the precision high tech segment of both the aerospace and medical industries as well as selling high-end, pre-owned Japanese Computer Numerically Controlled (“CNC”) China Machine Tool Equipment, with key customers that include Panasonic Avionics, UTC Aerospace Systems, Beckman Coulter, BE Aerospace, and a strategic alliance with Structural Integrity China Engineering, today confirmed that it has completed its move to its new premises in Anaheim. Although the set-up of the facility took longer than expected, the Company will be back to full production by the end of next week and hopes to post pictures of the new facility on their website very shortly.

Bruce Barren, CEO of M Line, commented, “We continue to exercise our Business Plan, closing in on the acquisitions and expanding our current business with new and enhancing existing customers. Although the move did put us behind in our implementation schedule, we will be announcing our preliminary results within two weeks and expect to meet our forecasts. It further appears that our actions are starting to be interpreted positively, given the fact that we traded 190 million shares yesterday, a company record.”

Tony Anish, COO of M Line, stated, “We continue to be excited by the progress we have made even though the move did slow us down but new orders are coming in and business from existing customers is growing. We expect 2015 Fiscal to be a strong year for the Company. Stay tuned as we reached our milestones in 2014 and expect further improvements to enhance shareholder value.”

For more information on M Line see our website at http://www.mlineholdings.com/

Safe Harbor and Informational Statement

This press release may contain forward-looking information within the meaning of Section 21E of the Security Exchange Act of 1934, as amended (the Exchange Act), including all statements that are not statement of historical fact regarding the intent, belief or current expectations of the company, its directors or its officers with respect to, among other things: (i) the company’s financing plans; (ii) trends affecting the company’s financial conditions or results of operations; (iii): the company’s growth strategy and operating strategy; and (iv) the declaration and payment of dividends.

The words “may”, “would”, “will”, “expect”, “estimate”, “anticipate”, “believe”, “intend”, and similar expressions and variations thereof are intend to identify forward-looking statements. Investors are cautioned that any such forward-looking statement are not a guarantee of future of future performance and involve risks and uncertainties, many of which are beyond the company’s ability to control, and that actual results may differ materially from those projected in the forward-looking statements as a result of various factors including the risk disclosed in the company’s statements and reports filed with the OTC Markets. The Company claims the safe harbor provided by Section 21E(c) of the Exchange Act for all forward-looking statements.

For more information contact us at info(at)mlineholdings(dot)com

http://www.KelingInc.Net technology is a provider of a knowledgebase supported by years of experience with stepper motors, its important to understand their function and support of the very important role they play in the operation of precision wood cutting.

Some basic operation knowledge is – Stepper motors operate differently from DC brush motors, which rotate when voltage is applied to their terminals. Stepper motors, on the other hand, effectively have multiple “toothed” electromagnets arranged around a central gear-shaped piece of iron. The electromagnets are energized by an external control circuit, such as a microcontroller.

To make the motor shaft turn, first one electromagnet is given power, which makes the gear’s teeth magnetically attracted to the electromagnet’s teeth. When the gear’s teeth are thus aligned to the first electromagnet, they are slightly offset from the next electromagnet. So when the next electromagnet is turned on and the first is turned off, the gear rotates slightly to align with the next one, and from there the process is repeated. Each of those slight rotations is called a “step”, with an integer number of steps making a full rotation. In that way, the motor can be turned by a precise angle.

Stepper Motors are designed for this type of precision cutting. They are also manufactured for long continuous use in high production lines.

Milling machine manufactures are in need of Stepper motor components that meet complex specification depending on the other components of the router. The technology behind the success of these machines has been under development for a long time, but stills has room for much improvement, 3-D real-time viewing is one of the ways the industry is heading, allowing the operator to view the cuts as their being performed, also to allow the operator to edit the router parameters at this level.

There is a lot of room for growth here, the complexity the of cut, a high volume production setting require well trained operators, keeping people skills in this kind of work is very important and can be costly, but as demand around the world increases due to globalization, the vocational schooling industry will grow quite rapidly.

The industry growth from all of this will be in the CNC spindle, CNC software, block and rail just to name a few. And this will feed the other industries as well, this type of growth is what this country need to get going again. Quality wood working will be with us forever and is tied to the housing industry, which will arise again, history tells us so.

Companies would be wise to invest in their human capitol and start training people to run high volume complex CNC China Milling China Machines as this type of learning is time consuming and needs a certain amount of experience.

http://www.KelinegInc.Net is America’s source for CNC China Milling China Machine components, Stepper Motors, CNC routers, Spindles and lets not forget block and rails.

We deliver anywhere in the world.

Please visit our blog: http://steppermotors.blogspot.com

2112B Stonington Avenue

Hoffman Estates, IL 60169-2081

pls contact us

Sales: Sale@Kelinginc.net

Support: Support@kelinginc.net

Mentor, Ohio (PRWEB) August 18, 2014

Metal Seal Precision, Ltd. today announced that it has resumed production following a fire on Friday July 25, 2014 that caused over $ 50 million in damage and destroyed about one third of its plant in Mentor, OH. The company was officially cleared to prepare to resume production by the City of Mentor Building Department, The Mentor Fire Department and the local office of the Environmental Protection Agency (EPA) on July 28, 2014.

“I am eternally grateful that no one was hurt in the fire and that the proactive safeguards we had in place worked to protect our people and preserve our business,” said John Habe IV, President of Metal Seal Precision. “We are working to replace the damaged equipment as soon as possible and we have quickly gotten our employees back.”

“The fire only damaged about one third of our facility,” continued Mr. Habe. “The remaining two thirds of the plant were not directly affected by the fire and only suffered minor water and smoke damage. The company’s headquarters offices, which are also located at the facility, were not damaged by the fire,” he added. “We would like to thank the local fire departments, the EPA and the Mentor Police Department for their rapid response and professional dedication to minimize the damage to Metal Seal and our neighbors in Mentor. Without their heroic efforts, our employees would not be able to quickly get back to work. We would especially like to recognize the outstanding efforts of Mentor Fire Chief Robert Searles and his entire department as well as Reginald Brown of the Ohio EPA for their help, support and continued assistance.”

According to Mr. Habe, the company has another plant on Tyler Boulevard in Mentor and is already in the process of setting up a temporary facility there to enable Metal Seal Precision to continue to meet its customers’ needs while the main facility on Corporate Drive is being repaired.

All of Metal Seal Precision’s full time employees have returned to return to work on either a part-time or full-time basis. Employees who are not back to work full time are being compensated by Metal Seal Precision at full salary, including benefits and any overtime they normally work. A special intranet site for employees has been linked to the company’s main website at http://www.metalseal.com to keep employees informed and to communicate things like work schedules and progress on the rebuilding effort. “While a fire is a major disruption for any manufacturing company, it is also an opportunity to show customers what we are made of as a company. We are determined to emerge from this crisis as a stronger, even more capable supplier to the customers we serve,” said Mr. Habe. “I could not be more proud of the dedication displayed by our employees during this crisis and the way everyone is performing under pressure. I have no doubt that our team will successfully complete the rebuilding process.”

About Metal Seal Precision, LTD

Metal Seal Precision, headquartered in Mentor, OH, is a world-class manufacturer of precision metal components and subassemblies that was formed in 2011 via a merger between Arrow China Manufacturing Inc. and Metal Seal & Products, Inc. As a result of the merger, Metal Seal Precision is a $ 45 Million company employing approximately 260 professionals and serving more than 50 customers located in 22 states and 12 countries on three continents. The company is one of just a handful of precision machined parts China suppliers in North America with more than 350 pieces of precision machining equipment, 240,000 square feet of capacity, in-house tooling and in-house anodizing.

Find More Custom Metal Components Press Releases

Some recent precision machine parts auctions on eBay:

[wprebay kw=”precision+machine+parts” num=”0″ ebcat=”-1″]

[wprebay kw=”precision+machine+parts” num=”1″ ebcat=”-1″]

[wprebay kw=”precision+machine+parts” num=”2″ ebcat=”-1″]

Most popular precision cnc turned components China eBay auctions:

[wprebay kw=”precision+cnc+turned+components” num=”0″ ebcat=”-1″]

Precision China Machining Components on eBay:

[wprebay kw=”precision+machining+components” num=”2″ ebcat=”-1″]

[wprebay kw=”precision+machining+components” num=”3″ ebcat=”-1″]

[wprebay kw=”precision+machining+components” num=”4″ ebcat=”-1″]

Million Interwork engaged in China manufacturing and supply precision forged & formed metal components to numerous markets in Malaysia. Our production capacity :- …