Check out these turning parts China manufacturer images:

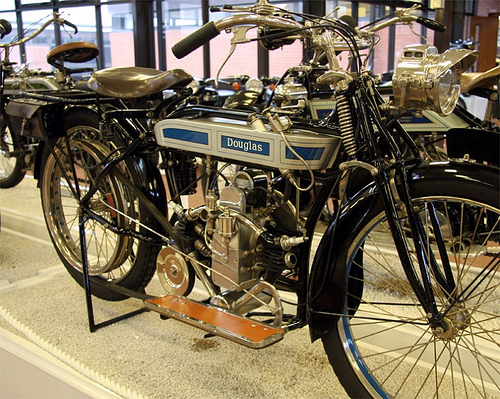

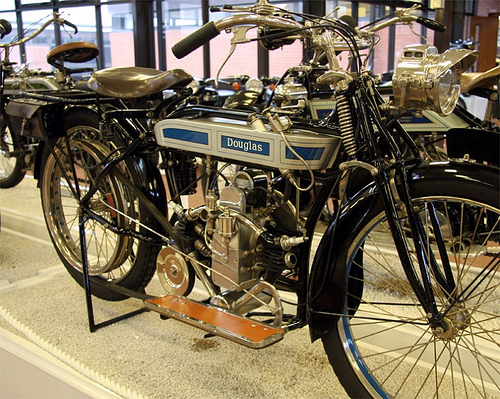

Douglas Motorcycles (Bristol) Timeline

Image by brizzle born and bred

In 1882, William Douglas and his brother Edward Douglas founded the Douglas China Engineering Company, first as a blacksmith’s shop, but soon expanded to become an iron founders making quality castings, and later supplied parts to Joseph Barter, of Light Motors, for his Fairy engine. After the turn of the century and the advent of the motor vehicle they soon became involved in the development of engines.

•1885 Company founded.

•1907 The first model was introduced at the Stanley Show. Mounted high in the frame, it had a 2.75hp flat-twin engine with braced forks and direct-belt drive. They also exhibited a compact V4 engine, but only two or three of these were made as the design was too advanced for the times.

•1909-1912 New frame design brought changes. A two-speed gearbox became available and a ladies’ model was produced. Douglas began supplying Williamson with 8h p flat-twin engines for their machines. They also had their first success at the TT, with a win in the Junior class.

•World War I. Several models were used by the forces and approximately 25,000 of these reliable machines went for service use. After the end of the war surplus bikes flooded the civilian market until around 1920.

•1920 The W20 model, with its 2 cylinder, 348cc sv engine, was equipped with clutch, kick starter and three-speed gear. It has a quite a few accessories, such as handlebar mounted watch, speedometer, full Lucas acetylene lighting, leather knee pads, protective shield under crankcase, holder for spare spark plugs and round leather case for spare tube or belt.

•1920s During the decade, Douglas had a Royal Warrant for supplying motorcycles to Prince Albert (late King George VI) and Prince Henry. Even King George V acquired a Douglas machine in this period.

•1921 The 3.5hp model was dropped and pivot-forked rear suspension made a brief appearance. This was followed by the introduction of two models with ohv engines.

•1923-1925 The firm did well in the TT and proved that their motorcycles were good performers in many classes. During this period Cyril Pullin became Chief Designer for Douglas.

•1926 An ‘all-new model’ was launched as the EW – designed to appeal to those who demanded performance without a high price tag.

•1927 By now there were five versions of the EW, and although a serious fire damaged the works, Douglas saw success in Australian dirt-track racing, as the low-slung design was well suited to the terrain.

•1928 Cyril Pullin left the firm, to be replace by Freddie Dixon, who produced a racing TT model. It was later joined by a dirt-track model designed specifically for speedway.

•1931 The firm had become a public company and it was sold by the family.

•1932 New models were added, but the firm was soon in financial difficulty.

•1934 They produced a 494cc shaft-drive model called the Endeavour. William Douglas, by now quite elderly, bought back the faltering business and produced a smaller range until the end of the decade.

•1935 They were in financial trouble and were taken over by BAC.

•1935 Public company named as Aero Engines Ltd.

•1939-1945 During the war, Douglas made other products.

•1946 Name changed.

•1947-1950 Douglas launched various new models. In 1948, Douglas was again in economic distress and forced to rationalize its line to a series based on a 350cc flat twin.

•1951 A 500cc prototype was shown, but never made. An agreement was made for the company to build the Italian Vespa scooter under licence.

•1955 The last model made was the advanced and novel 350cc Dragonfly. Distinctive looks and good handling could not hide the low top speed (75mph, although a sports model claimed 84mph) and poor low-rev performance.

•1956 The firm was taken over by Westinghouse Brake and Signal Co.

•1957 The Vespa was still imported, but the end of the Douglas was close.

•1961 Light engineers and metal founders, specialising in the manufacture of Vespa Motor Scooters, Road Brakes and Signal and Colliery Equipment. 2,000 employees.

•Note: For many years afterwards, still trading under the Douglas name, the company imported Gilera mopeds and lightweight motorcycles.

Joseph Barter of Aston Gate, Bristol were motorcycles produced from 1902 to 1905.

•1902-5 The machines were designed by Joseph Barter. The engine had its drive pulley mounted on the camshaft so that, as it was larger than usual, belt slip was reduced. It was a primitive affair with the engine inclined above the frame downtube and only a few were built. Joseph Barter then moved on to a flat-twin engine design, firstly called Fée then Fairy, and the forerunner of the Douglas.

Fairy was a motorcycle produced from 1906 to 1907.

It was the anglicized name of the Fée, built by Joseph Barter of Bristol in 1905.

The machine had a 2.5hp flat-twin engine fitted high in a stock bicycle frame, with transmission by chain to a counter-shaft and clutch, then by belt to the rear wheel.

In 1907, after Joseph Barter had joined Douglas, the name was taken up by them.

Fée was a motorcycle produced in 1905 by Joseph Barter of Bristol.

Joseph Barter had first produced a single-cylinder machine prior to this. He offered it under his own name until, in 1905, he turned to a flat-twin engine. Later it was known as the Fairy and was the fore-runner of the Douglas.

The Fée engine was 2.5hp and mounted high in the frame of a stock bicycle with braced forks. It had a large flywheel on the left and the transmission was by chain to a countershaft. This carried a clutch and then went by belt to the rear wheel.

Within a year the name had been anglicized to Fairy.

•1905-05 Barter designed side-valve flat twins with 198cc / 346cc / 676cc engines. Also known as the Fairy.

Williamson Motor Co of Earlsdon, Coventry. Also as A. Williamson and Co.

•Company formed by William Williamson when he left the Rex Motor China Manufacturing Co. Maker of cars from 1913 and motorcycles produced from 1912 to 1920.

•1912 The first machine made it debut and offered power with silence, and no vibration, courtesy of its 8hp flat-twin water-cooled engine, made for them by Douglas of Bristol. As it was part of their stationary engine range, it had a starting handle, like that of a car. It was a typical Douglas engine with side valves, gear-driven magneto and was installed low down in a long frame to drive a two-speed Douglas gearbox with all-chain drive.

•1913 An air-cooled version was added, but it did not sell as well as the quieter machine and had a tendency to over-heat. It did, however, continue to be offered as an option. Most models sold were water-cooled and used for sidecars.

•1916 Production continued until that year, and then stopped until after the War.

•1919 Late in the year they returned with the air-cooled flat-twin and a new model with the 771cc sv JAP V-twin engine and three-speed Sturmey-Archer gearbox with all chain drive.

•1920 Only the V-twin remained, this being sold with the sidecar as a complete combination. It was their final year of production.

Cyril George Pullin (1893-1965) was a British, inventor, engineer and motorcycle race driver born in Hammersmith.

In 1914 Pullin won the Isle of Man TT race. In the 1920’s he developed the Ascot car and had various helicopter engine patents.

In 1925 he developed the Powerwheel, a single cylinder rotary engine in the hub of a motorcycle wheel, including clutch and drum brakes. His sister was married to Stephen Leslie Bailey, a then prominent engineer at Douglas Motors, and many of his patents were filed under the name of that company.

Brown and Roper was a motorcycle produced in 1921.

This machine was the concept of two engineers named Messrs Brown and Roper of Salisbury, Wiltshire.

An attempt was made to produce a marketable single-track two-wheeler that was enclosed by an open car in order to offer weather protection. The basis was a 4hp sv flat-twin Douglas engine in a lengthened frame. This allowed the rider to be seated low down, in a space created between the existing saddle tube and the rear wheel.

Outrigger wheels were carried on an auxiliary frame. A lever on the right could be used to lower or raise those wheels, in order to keep the machine upright when at rest. A wheel set immediately in front of the rider and connected to the fork top by tensioned long rods, provided the steering mechanism. It had a Douglas three-speed chain-cum-belt gearbox and transmission, and access to working parts was easy. It is not thought that any machines other than the prototype were ever built.

British Roadless was a motorcycle produced in 1920.

This short-lived machine was an early experiment in tracked motorcycles. It propelled itself with a rubber V-belt that ran around the front and rear wheels. These were formed as pulleys with a series of miniature bogies on the lower run. It was fitted with a 348cc Douglas flat-twin engine mounted above the rear wheel and was steered by turning the front wheel a little. As it lacked both grip and stability, it was not around for long.

The British Aircraft Co was founded in 1928 to build gliders

•1932 The founder C. H. Lowe Wylde fitted a Douglas 600cc engine to the BAC VII Tandam to produce the Planette.

•Two more were built but on 13th May 1833 Lowe Wylde was killed while demonstrating it.

•The company was acquired by Robert Kronfeld and renamed Kronfeld in 1936 but the company closed in 1937.

Untitled

Image by Ed Yourdon

This was taken on the southwest corner of Broadway and 96th Street. I took half a dozen quick "hip shots", because I was standing fairly close to them, and didn’t want them to notice me as I photographed them. While this was the best of the collection, unfortunately I inadvertently cut off part of their shoes.

Note: this photo was published in a Sep 6, 2009 blog titled "Homo Junkiens."

Moving into 2010, the photo was published in a Jan 10, 2010 blog titled "Childhood Obesity Statistics." And it was published in a Jan 26, 2010 blog titled "Michelle Obama targets childhood obesity." It was also published in a Mar 10, 2010 blog titled "Hallan nuevas alteraciones de la diabetes tipo 2 en jóvenes." And it was published in an undated (Mar 2010) all-about-obesity-dot-com blog , with the same title as the caption that I used on this Flickr page. It was also published in an undated blog titled "Childhood Obesity Statistics 2009: Images." And it was published in an Apr 13, 2010 blog titled "The Problem With Our War on Obesity." It was also published in an undated (Apr 2010) Squidoo blog titled "Adrenal Fatigue Diet," and an undated (Jul 2010) BennyHollywood blog titled "A Picture is Worth… In 1991 The Fattest US States Were As Thin As The Leanest in 2009." It was also published in a Sep 3, 2010 blog titled "Digital Camera Battery Tips." And it was published in a Sep 27, 2010 blog titled "Deutschland ist zu dick."

Moving into 2011, the photo was published in a Feb 13, 2011 blog titled "Childhood Obesity Statistics." It was also published in an Apr 5, 2011 blog titled "Arizona proposes fee for obese or smoking Medicaid recipients." It was also published in an Apr 28, 2011 blog titled "If You See Overweight People Will You Eat More?" And it was published in a Jul 2, 2011 blog titled "Según el informe Aladino 2011 la obesidad aumenta entre los niños españoles," as well as a Jul 6, 2011 blog titled "Diabetes: Getting Worse Every Day in Every Way." It was also published in an Aug 10, 2011 blog titled "Why There’s More Money in Maintaining the Obesity Crisis Than Ending It." And it was published in an Oct 5, 2011 blog titled "Is a ‘fat tax’ the answer to Australia’s obesity crisis?", as well as an Oct 13, 2011 blog titled "La obesidad infantil y sus consecuencias INTRODUCCION." It was also published in an Oct 14, 2011 blog titled "Desarrollo." And it was published in an Oct 16, 2011 blog titled "Problemas acarreados por la obesidad: Obesidad Infantil y sue consecuencias." It was also published in a Dec 16, 2011 blog titled "Childhood Obesity Rates Drop, But Disparities Remain."

Moving into 2012, the photo was published in an undated (early Jan 2012) blog titled "How Does Obesity Cause Diabetes?" It was also published in a Jan 17, 2012 blog titled "Quitting Smoking Among Adults: United States 2001-2010" And it was published in a Feb 15, 2012 blog titled "School Furniture Manufacturers Are Now Making Larger Desk Chairs For Fat Students." It was also published in a Mar 15, 2012 blog titled "Is It Counter Productive That the Whitehouse Wants to Fund the New?", as well as an Apr 15, 2012 blog titled "How to Prevent Childhood Obesity?" It was also published in a Jun 8, 2012 blog titled "Science, Evolutionary Biology, And Simple Economics Say Bloomberg’s Soda Ban Is Right." And it was published in an Aug 30, 2012 blog titled "17 Things That Make You Dumber." It was also published in a Sep 21, 2012 blog titled "Additivi nella plastica? Il Bisfenolo A promuove l’obesità." And it was published in a Sep 26, 2012 blog titled "Childhood Obesity and Soda: Science Says It’s A Problem, Soda Companies Say It’s Not." It was also published in an Oct 29, 2012 blog titled "Why God Hates New York." And a severely cropped version of the photo was published in a Dec 7, 2012 blog titled "Should fat make the grade on report cards?"

Moving into 2013, the photo was published in a Jan 24, 2013 blog titled "Overweight and Obese People Need More Fat-Soluble Vitamins – Part 1 of 2." And it was published ina Feb 8, 2013 blog titled "Is it OK to make fun of overweight people?" It was also published in a Feb 22, 2013 blog titled "Dear Junk Food: We Love You, But You’re Bringing Us Down." And it was published in an undated (late June 2013) blog titled "24 Uplifting Short Hairstyles For Fat Women." Note: A cropped version of the photo was published in a blog titled "STUDY: ‘Fat shaming’ increases chance of becoming obese." It was also published in an Aug 16, 2013 blog titled "Obesity in America Is Three Times More Deadly Than We Thought."

****************************

This is the continuation of a photo-project that I began in the summer of 2008: a random collection of "interesting" people in a broad stretch of the Upper West Side of Manhattan — between 72nd Street and 104th Street, especially along Broadway and Amsterdam Avenue.

As I indicated when I started this project in 2008, I don’t like to intrude on people’s privacy, so I normally use a telephoto lens in order to photograph them while they’re still 50-100 feet away from me; but that means I have to continue focusing my attention on the people and activities half a block away, rather than on what’s right in front of me.

I’ve also learned that, in many cases, the opportunities for an interesting picture are very fleeting — literally a matter of a couple of seconds, before the person(s) in question move on, turn away, or stop doing whatever was interesting. So I’ve learned to keep the camera switched on (which contradicts my traditional urge to conserve battery power), and not worry so much about zooming in for a perfectly-framed picture … after all, once the digital image is uploaded to my computer, it’s pretty trivial to crop out the parts unrelated to the main subject.

Thus far, I’ve generally avoided photographing bums, drunks, crazies, and homeless people. There are a few of them around, and they would certainly create some dramatic pictures; but they generally don’t want to be photographed, and I don’t want to feel like I’m taking advantage of them. I’m still looking for opportunities to take some "sympathetic" pictures of such people, which might inspire others to reach out and help them. We’ll see how it goes …

The only other thing I’ve noticed, thus far, is that while there are lots of interesting people to photograph, there are far, far, far more people who are not so interesting. They’re probably fine people, and they might even be more interesting than the ones I’ve photographed … but there was just nothing memorable about them.

Xatarra i xinet

Image by art_es_anna

LA ALDEA CHINA QUE CAMBIÓ ARROZ POR CHATARRA.

El 80% de lo habitantes de Guiyu sobreviven gracias al desguace de artículos electrónicos poniendo en riesgo su salud

Un niño rodeado de escombros de cables y basura electrónica. EFE.

Efe, Pekín (China)

Los habitantes de Guiyu, en la desarrollada costa china, han abandonado el cultivo del arroz como medio de vida por un negocio mucho más rentable pero implacable con su salud y el medio ambiente: el reciclaje de la basura electrónica del resto del mundo.

El 70% de los desechos electrónicos del planeta están en China y buena parte de ellos llegan, en violación de la Convención de Basilea, desde los países desarrollados hasta el puerto de Nanhai, en la provincia suroriental de Cantón.

Desde allí, una red ilegal de importadores los transportan a la pequeña localidad de Guiyu.

Entre colinas de teclados, cables y placas, hombre, mujeres y niños funden y destripan restos de artículos electrónicos, sobre todo ordenadores, sin apenas protección, lo que les convierte en presa fácil de las 700 sustancias tóxicas incluidas en esos objetos.

Con las manos desnudas, el 80% de los 150.000 habitantes de Guiyu buscan materiales como cobre, plástico o acero, que luego venden a los mercaderes de segunda mano.

"Muchos emigrantes rurales han llegado hasta Guiyu atraídos por unos salarios de entre dos y tres dólares la hora, muy superiores a lo que ganan en el campo", explica Jamie Choi, responsable de campaña de Greenpeace. "Tienen que elegir entre tener suficiente dinero para vivir o su salud", añade.

Nocivo para la salud

En este gran vertedero de la sociedad de la información apenas se usan máscaras y la herramienta más avanzada tiene forma de taladro, afirma.

Los perjuicios para la salud tienen un exponente demoledor: el 80% de los niños de Guiyu presentan niveles altos de plomo en la sangre, lo que causa en daños en el sistema nervioso y reproductor, según constató un estudio de la cercana Universidad de Shantou.

"Los niños, sobre todo los hijos de los emigrantes, se dedican a hacer las labores más sencillas. Están 24 horas trabajando, respirando, jugando con los materiales peligrosos", explica Choi.

Entre tanto, Wu Yuping, de la Administración Estatal de Medio Ambiente (SEPA), subraya que "no se puede encontrar agua potable en 50 kilómetros a la redonda", debido a que las sustancias tóxicas se amontonan en las riberas del río y se filtran de forma subterránea.

En 1994, la Convención de Basilea, suscrita por casi todos los países desarrollados menos Estados Unidos, prohibió la exportación de desechos peligrosos de los países ricos a los pobres, incluidos los destinados al reciclaje, pero su aplicación ha mostrado muchas lagunas.

"Greenpeace ha visto barcos que parten de Holanda a China, cargados de residuos electrónicos", dice Choi.

Y muchos llegan a Guiyu.

De vuelta al ‘primer mundo’

Entre las labores cotidianas está la de desarmar placas madre en un hornillo casero de carbón en busca de los codiciados chips, que contienen oro.

O también fundir las carcasas de los ordenadores para transformar el tóxico PVC en piezas que se destinan a objetos que, curiosamente, vuelven a acabar en el mundo occidental: las flores de plástico.

Cada año el planeta genera entre 20 y 50 millones de toneladas de desechos electrónicos, de acuerdo con datos del Programa de Naciones Unidas para el Medio Ambiente:el 80% acaba en Asia y de ese porcentaje el 90% llega a China.

Aunque Guiyu es el más célebre, hay otros vertederos de este tipo en Longtan y Tali, también en Cantón, en Taizhou (provincia de Zhejiang) y en la vecina Hunan, según alerta la SEPA.

Si bien la mayoría de los desechos proceden de los países ricos, China genera cada año 1,1 millones de toneladas, una cifra que se multiplica a medida que aumenta el nivel de vida.

"En los suburbios de ciudades como Pekín o Tianjin hay pequeñas chabolas dedicadas a desarmar objetos electrónicos que acaban en Guiyu", subraya Choi.

El Gobierno estudia un proyecto de ley para que los fabricantes de ordenadores, televisores, refrigeradores, lavadoras y aires acondicionados chinos se responsabilicen de reciclar sus productos.

Esa medida responde a las peticiones de los ecologistas, que consideran que son los fabricantes quienes tienen que asumir la responsabilidad por sus productos.

Sin embargo, dicen, no habrá solución definitiva sin pasos como el dado el año pasado por la Unión Europea: prohibir el uso de plomo, mercurio, cadmio, cromo hexavalente, bifenilos policromados y éter de bifenilo policromado en los aparatos electrónicos.

Hake me hizo reflexionar sobre este tema :

www.flickr.com/photos/hake/415111783/?#comment72157594578…

THE CHINESE VILLAGE THAT CHANGED RICE BY SCRAP IRON. 80% of the inhabitants of Guiyu survive thanks to the electronic article taking apart putting in risk their health a boy surrounded by rubbish of cables and electronic sweepings. EFE. Efe, Beijing (Chinese) the inhabitants of Guiyu, in the developed Chinese coast, has left the culture of the rice like means of life by a profitable but much more implacable business with their health and the medio.ambiente: the recycling of the electronic sweepings of the rest of the world. 70% of the electronic remainders of the planet are in China and good part of them arrives, in violation of the Convention of Basel, from the countries developed to the port of Nanhai, in the suroriental province of Corner. From there, an illegal network of importers transports them to the small locality of Guiyu. Between hills of keyboards, cables and plates, man, women and children found and gut rest of electronic articles, mainly computers, without hardly protection, which turns to them easy prey of the 700 toxic substances including in those objects. With the naked hands, 80% of the 150,000 inhabitants of Guiyu look for materials as it receives, plastic or steel, that soon sell the merchants of second hand. "Many rural emigrants have arrived until Guiyu attracted by wages from between two and three dollars the hour, very superior to which they win in the field", explains Jamie Choi, person in charge of campaign of Greenpeace. "They must choose between having sufficient money to live or its health", adds. Injurious for the health In this great garbage dump of the society of the information as soon as masks are used and the tool more outpost has drill form, affirms. The damages for the health have a demolishing exponent: 80% of the children of Guiyu present/display high lead levels in the blood, which cause in damages in the nervous and reproductive system, according to stated a study of the near University of Shantou. "the children, mainly the children of the emigrants, dedicate themselves to make the workings simplest. 24 hours are working, breathing, playing with the dangerous materials ", explains Choi. In the meantime, Wu Yuping, of the State Administration of Medio.ambiente (IT KNOWS), emphasizes that "potable water in 50 kilometers to the round one cannot be found", because the toxic substances crowd in the shores of the river and they filter of underground form. In 1994, the Convention of Basel, subscribed by almost all the developed countries less United States, prohibited the export of dangerous remainders of the rich countries to the poor men, including the destined one to the recycling, but its application has shown many lagoons. "Greenpeace has seen boats that leave from Holland for China, loaded of electronic remainders", says Choi. And many arrive at Guiyu. Of return to ‘ first mundó Between the daily workings she is the one to disarm plates mother in a homemade coal small furnace in search of coveted the Chips, that contain gold. Or also to fuse the housings of the computers to transform toxic PVC into pieces that are destined to objects that, peculiarly, return to finish in the western world: the plastic flowers. Every year the planet generates between 20 and 50 million tons of electronic remainders, in agreement with data of the Program of Nations United for the Means Ambiente:el 80% finish in Asia and from that percentage 90% arrive at China. Although Guiyu is most famous, is other garbage dumps of this type in Longtan and Tali, also in Corner, Taizhou (province of Zhejiang) and in the Hunan neighbor, according to alert KNOWS it. Although most of the remainders they come from the rich countries, Chinese generates every year 1.1 million tons, a number that is multiplied as it increases the standard of life. "In the suburbs of cities as Beijing or Tianjin are small dedicated shacks to disarm electronic objects that finish in Guiyu", it emphasizes Choi. The Government studies a law project so that the manufacturers of computers, television sets, refrigerators, washing machines and conditioneds air Chinese take responsibility to recycle their products. That measurement responds to requests of the ecologists, who consider that they are the manufacturers whom they have to assume the responsibility by his products. Nevertheless, they say, will be definitive solution without passages like the dice no the year last through the European Union: to prohibit the use of lead, mercury, cadmium, hexavalente chromium, policromados bifenilos and ether of bifenilo policromado in the electronic devices. Hake made me reflect on this subject: www.flickr.com/photos/hake/415111783/?#comment72157594578...